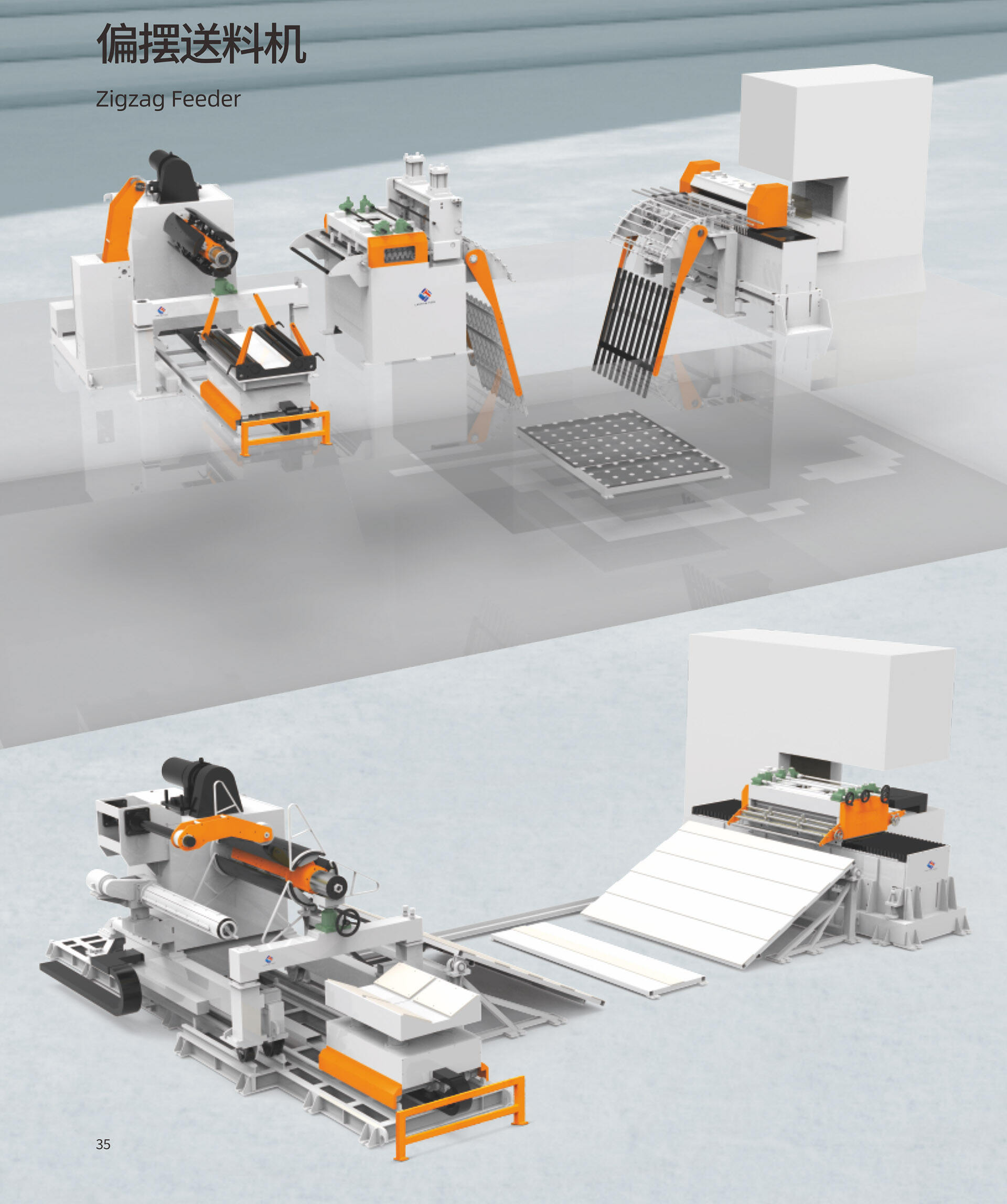

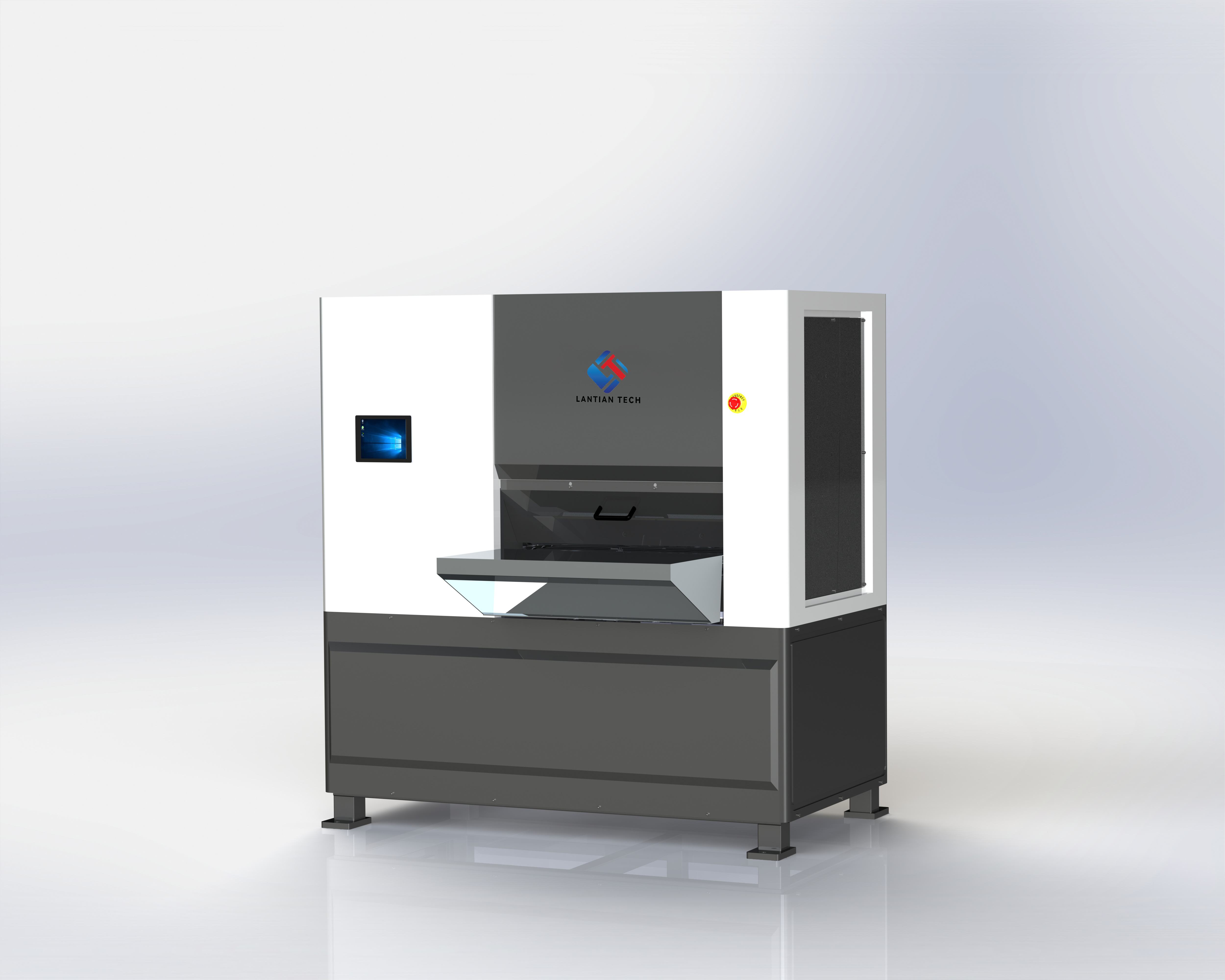

Zigzag Feeder

- Overview

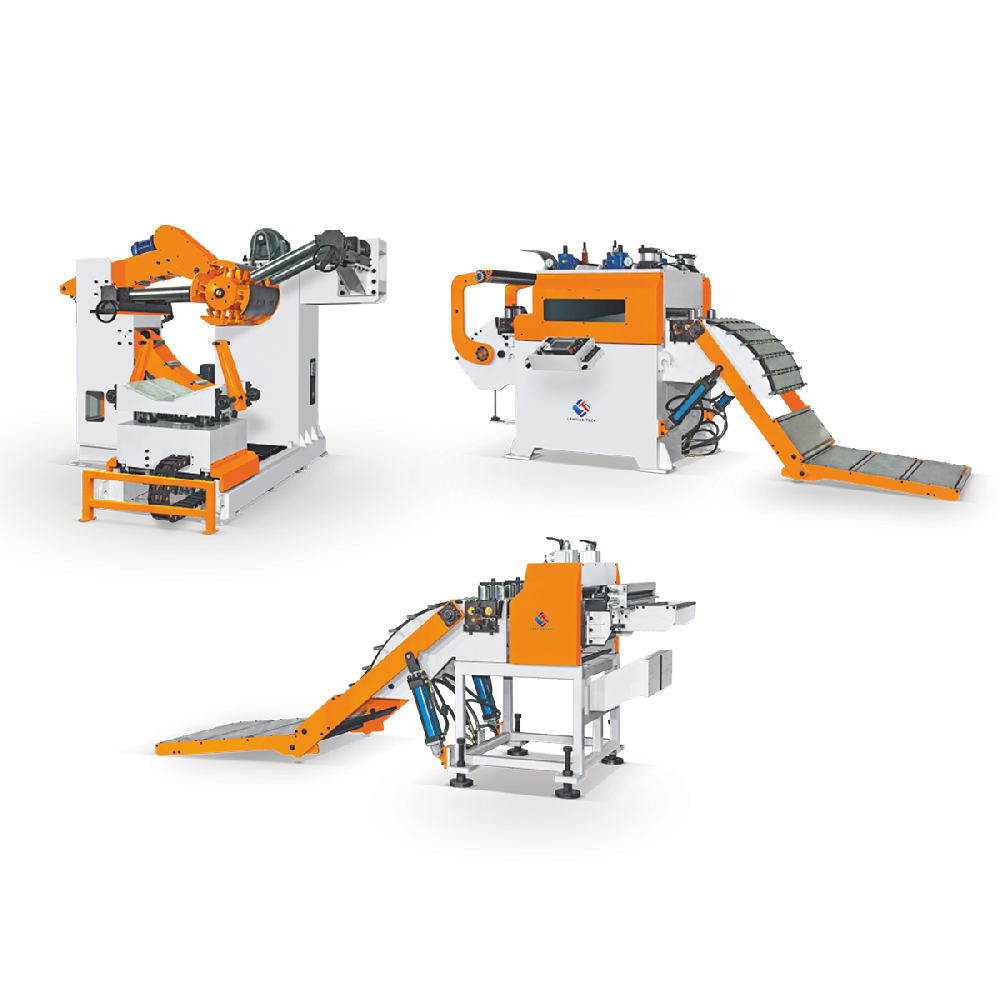

- Recommended Products

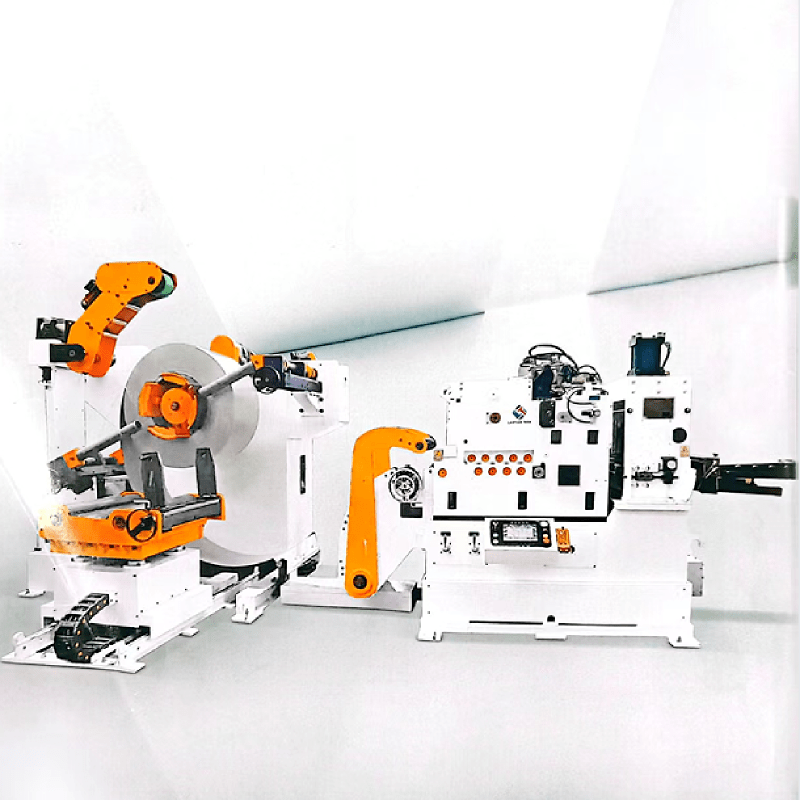

- The thickness of the material is: 0.3-3.2mm/0.5-5.0mm.

- Suitable materials include steel, copper, aluminum, special alloys and bimetals and other materials.

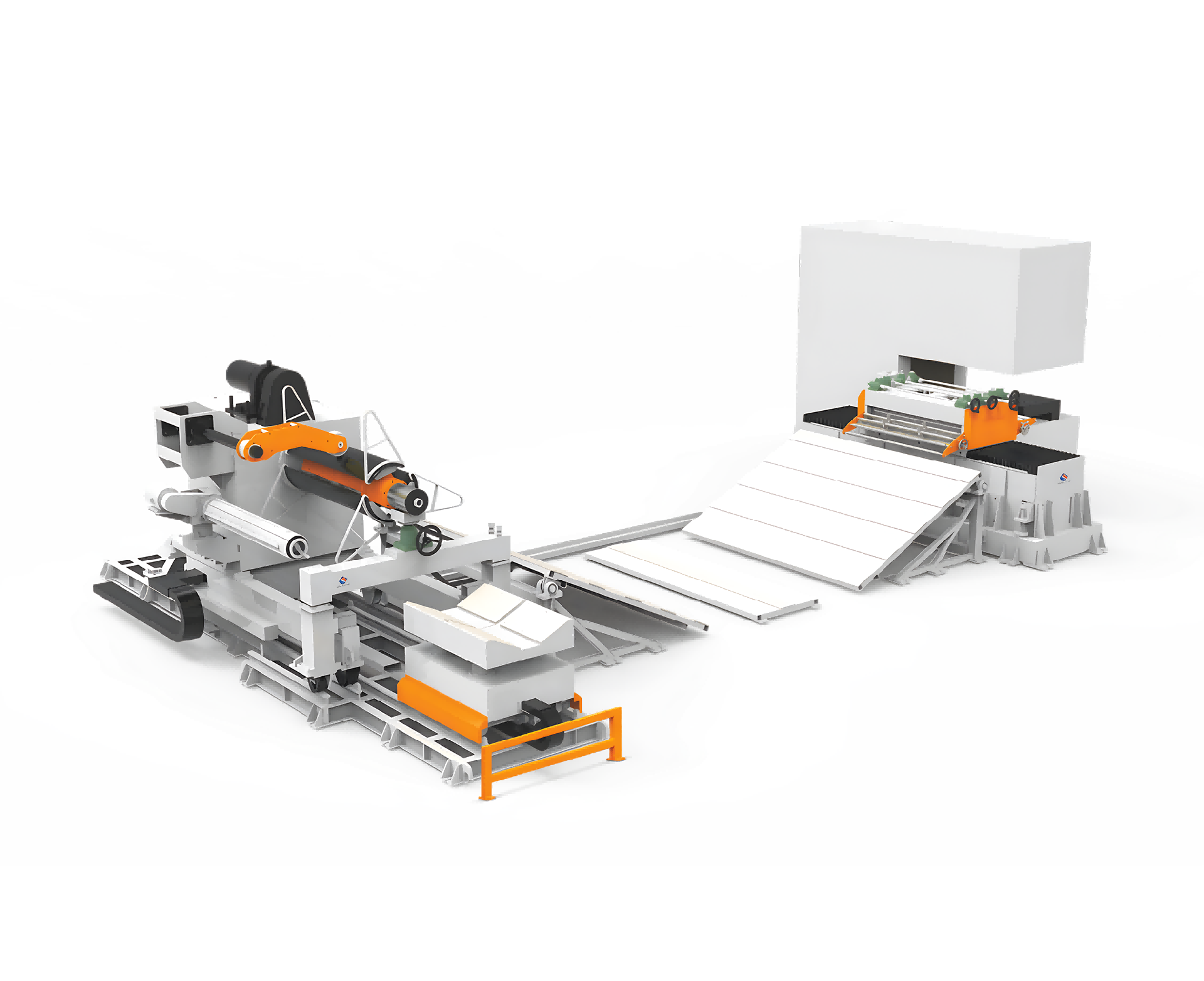

- High output: Can be shifted multiple times, calculate at a 60-degree angle, every shift saves 7% of material. When the original image size is not equal, the arrangement angle can be changed according to the width of the material to improve the utilization rate of the material.

- High efficiency: Maximum speed of 60 times per minute.

- High precision: During the continuous stamping process, the minimum distance between edges can be set within 0.5 millimeters. The error of each move can be guaranteed within ±0.1mm. Occupy less space, low energy consumption.

- Finished work is easy to transport: After material stamping,automatically fall onto the finished product conveyor belt. Delivered by conveyor belt to the pile stock table, full automation control.

- Save human resources: The production line is working, just one staff to operate the electric control box to control the cabinet. Enter the operating procedure on the man-machine panel, the equipment will produce fully automated.

Specifications:

Model |

LTZNCF-200 |

LTZNCF-300 |

LTZNCF-400 |

LTZNCF-500 |

LTZNCF-600 |

LTZNCF-800 |

LTZNCF-1000 |

LTZNCF-1300 |

LTZNCF-1500 |

Material Width(mm) |

200 |

300 |

400 |

500 |

600 |

800 |

1000 |

1300 |

1500 |

Material Thickness(mm) |

0.3-3.2 0.5-5.0 |

0.3-3.2 0.5-5.0 |

0.3-3.2 0.5-5.0 |

0.3-3.2 0.5-5.0 |

0.3-3.2 0.5-5.0 |

0.3-3.2 |

0.3-3.2 |

0.3-3.2 |

0.3-3.2 |

Feed Roller Diameter(Φ) |

66.5 |

66.5 |

66.5 |

66.5 |

66.5 |

90 |

90/120 |

120 |

120 |

Number of feed Feed Rollers |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

4 |

4 |

Leveling Roller Diameter(mm) |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

80 |

100 |

Number Of Leveling Rollers |

/ |

/ |

/ |

/ |

/ |

/ |

/ |

3 |

5 |

Maximum Offset(mm) |

200 |

300 |

400 |

500 |

600 |

800 |

1000 |

1300 |

1500 |

From The Pressing Method |

Air cylin |

Worm and Gear |

|||||||