Heavy Duty Swing Shear Cut To Length Line

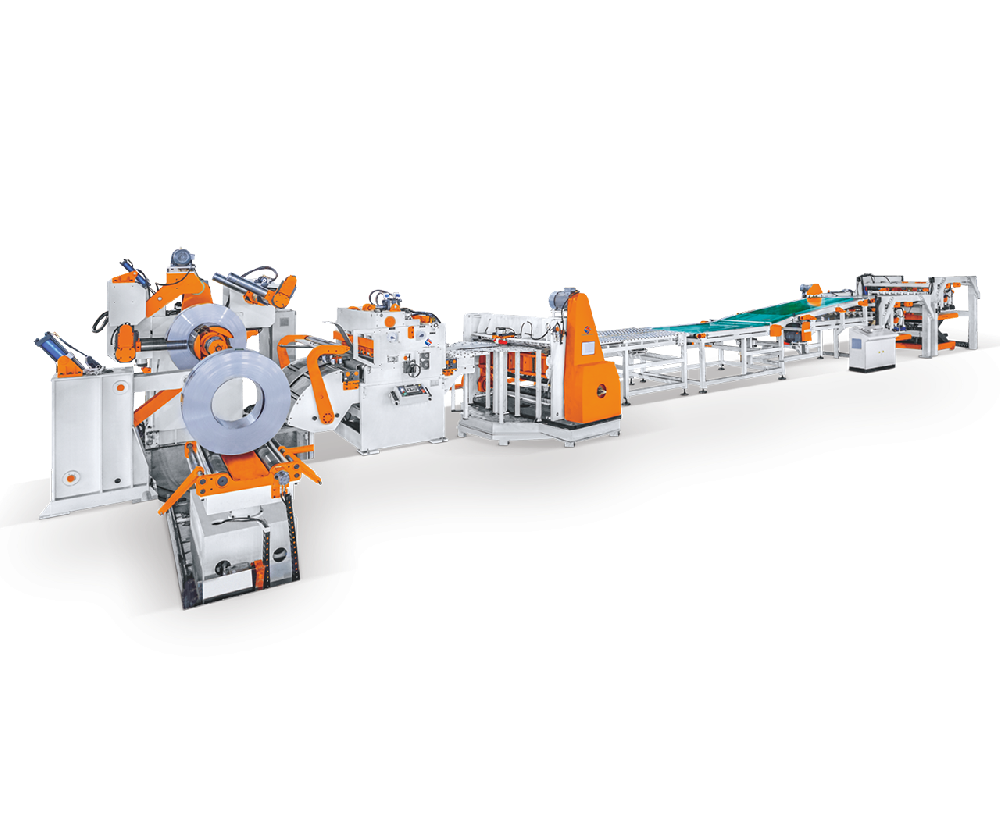

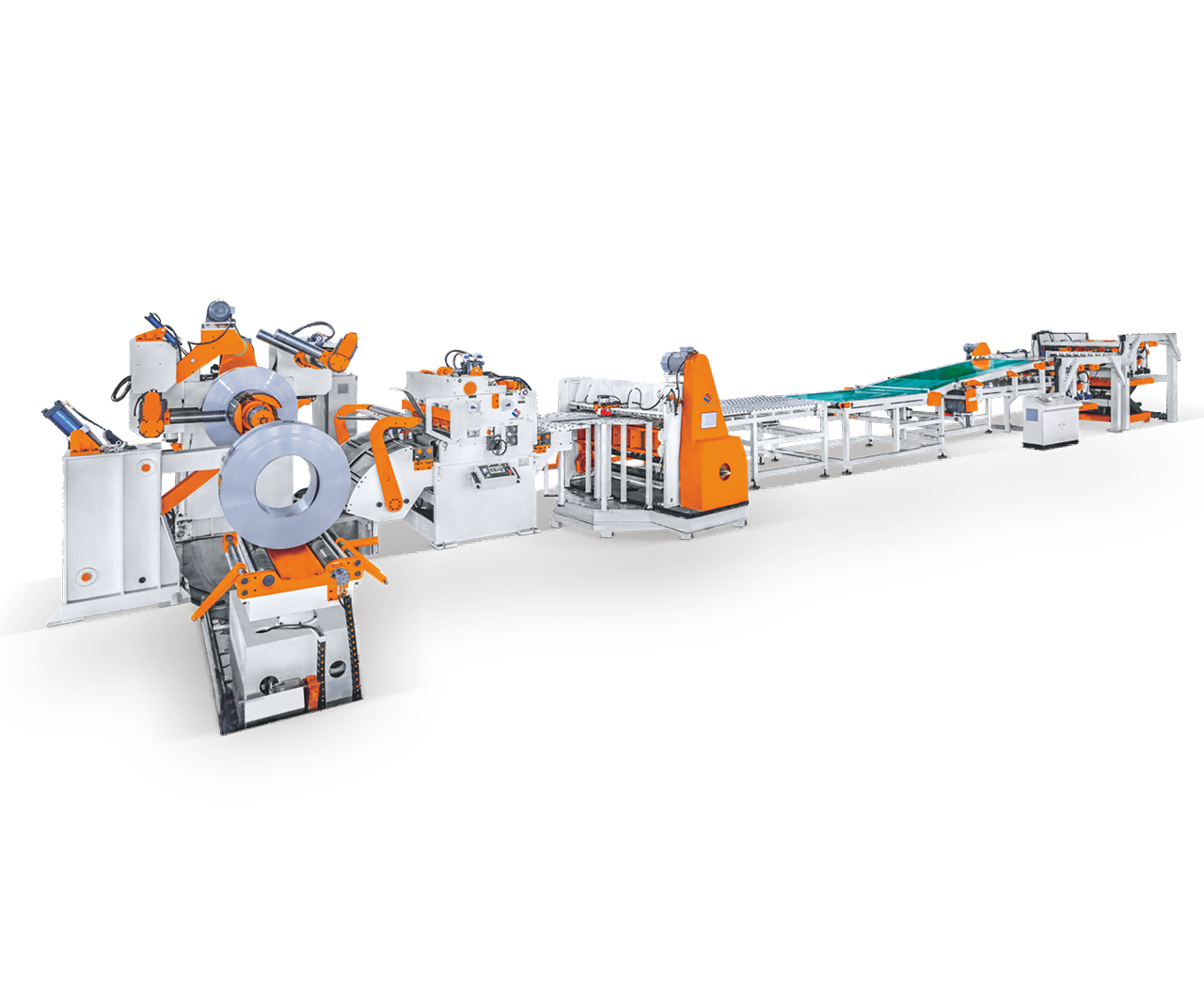

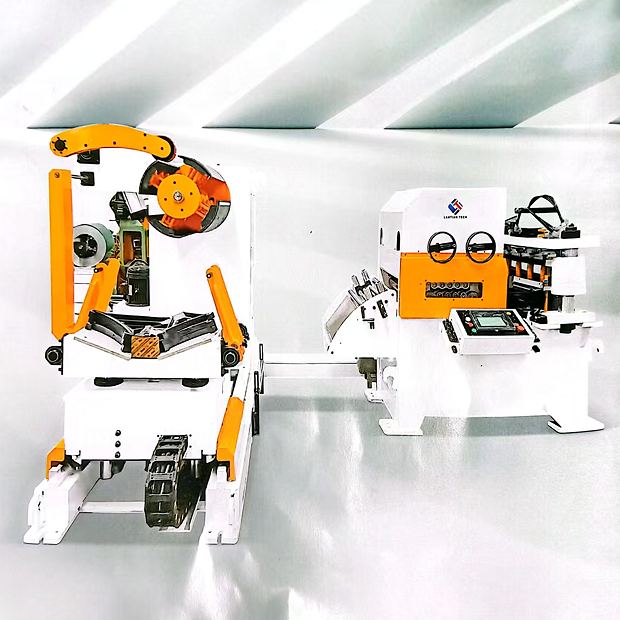

Heavy Duty Swing Shear Cut To Length Line is an important equipment for metal sheet processing.Firstly, the coil is uncoiled by the uncoiler, and after being leveled by the leveler, it is fed to the shearing by the feeding device. The shearing device cuts the plate into the required size and shape through the swinging cutting action. The cut plates are then stacked by the stacking device.

- Overview

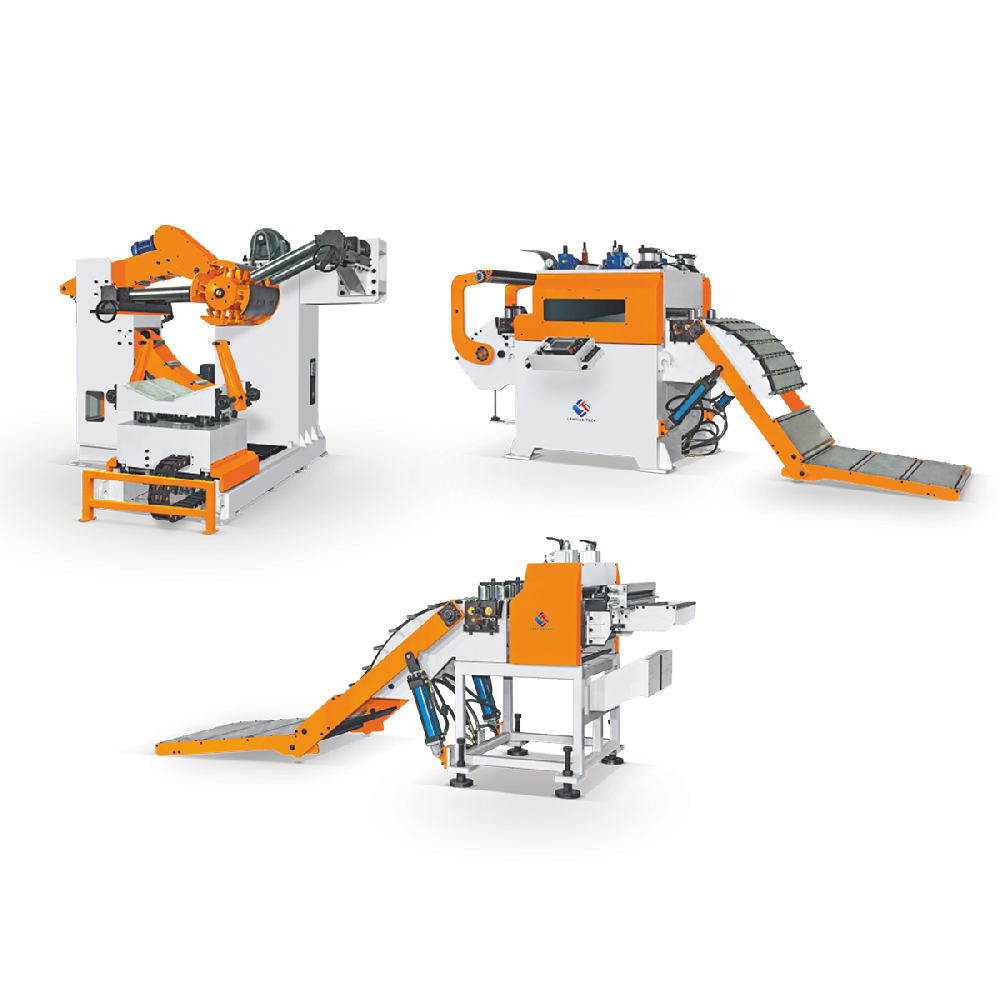

- Recommended Products