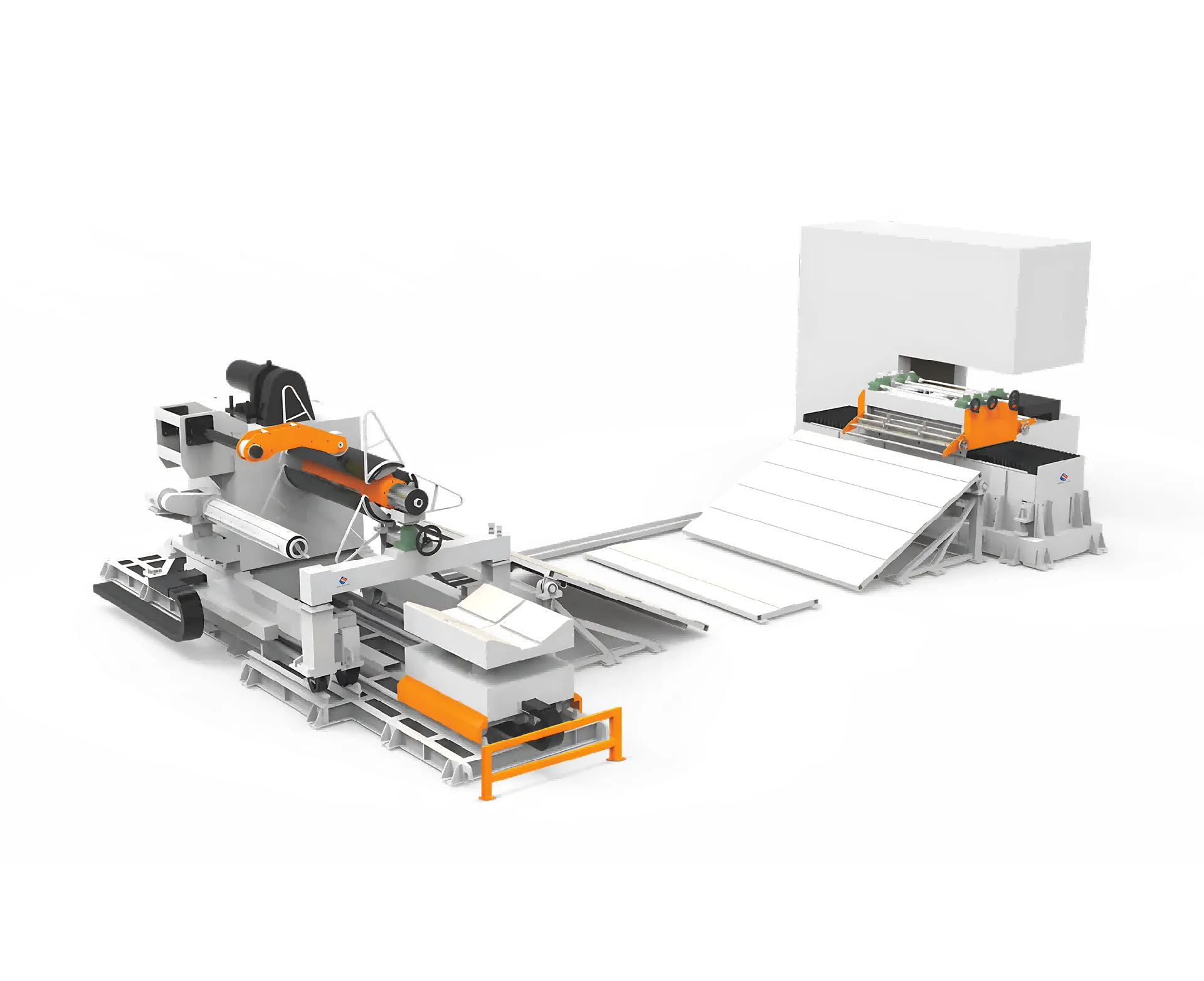

Manufacturing efficiency relies heavily on precise material handling systems that can consistently deliver components to production lines without disruption. A customized zigzag feeder represents one of the most sophisticated solutions for automated ...

VIEW MORE

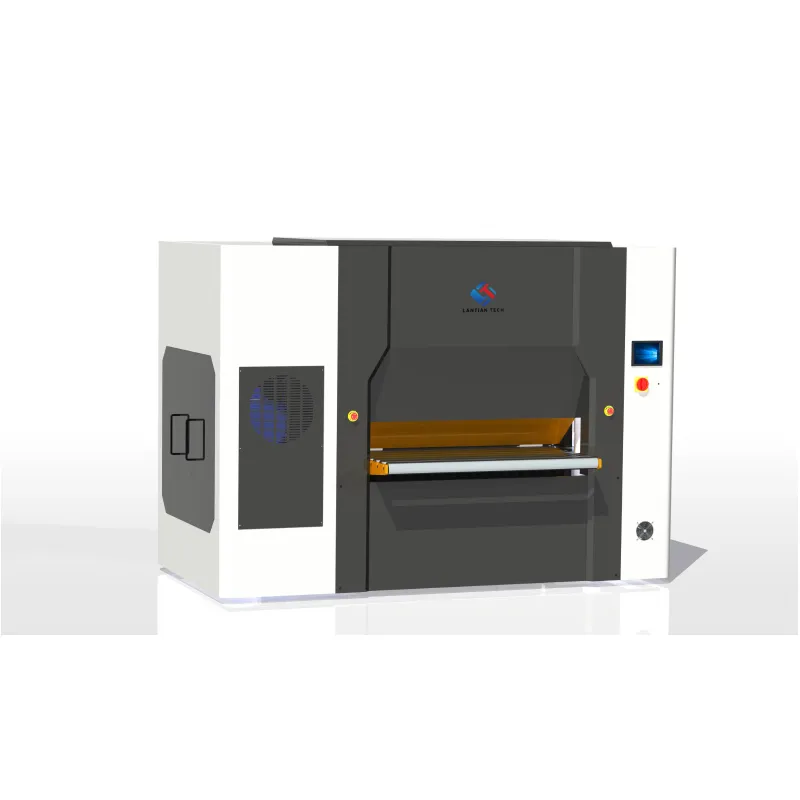

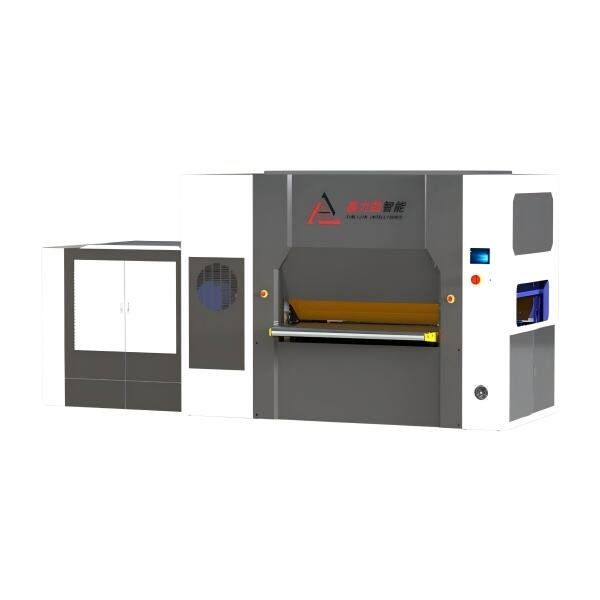

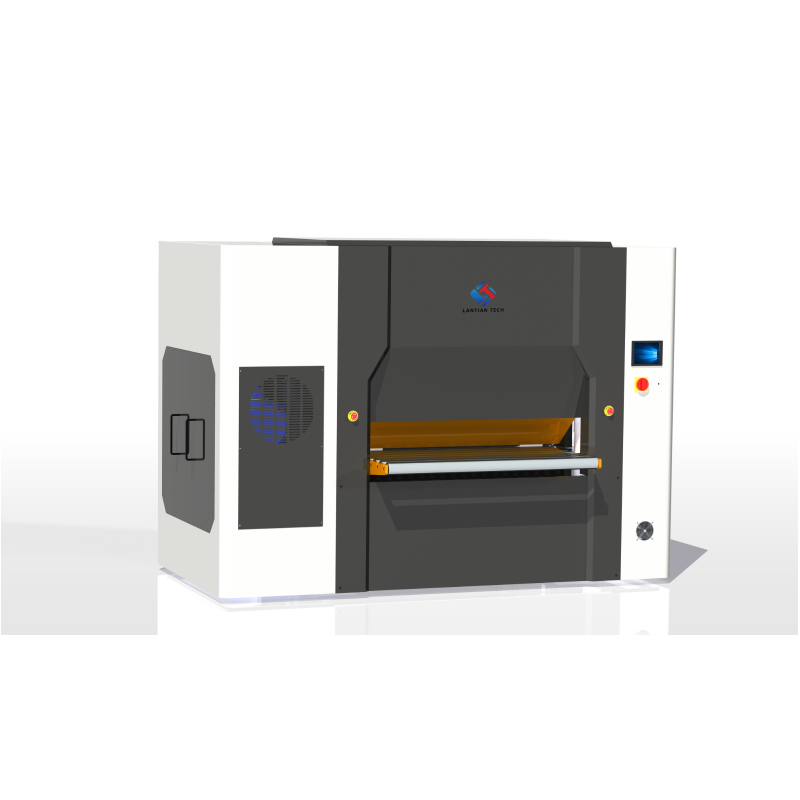

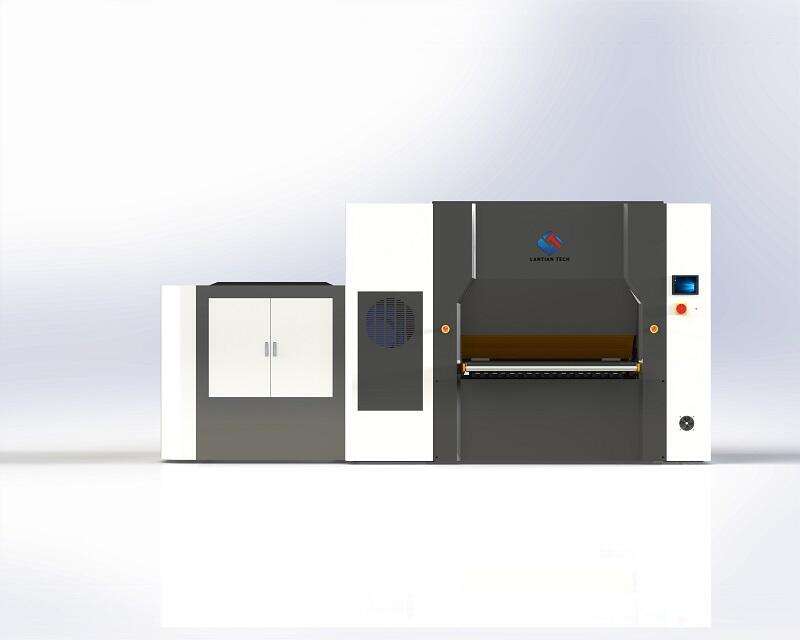

Multiroller CNC leveling machines have revolutionized the metal processing industry by delivering precise flatness correction for various materials including steel, aluminum, and stainless steel sheets. These sophisticated systems utilize computer-co...

VIEW MORE

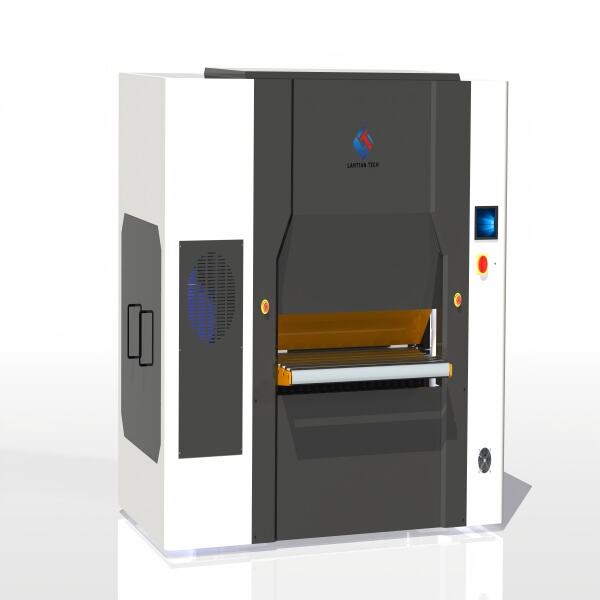

The manufacturing landscape demands precision and efficiency in metal processing operations, making the selection of appropriate leveling equipment crucial for B2B success. Advanced leveling technology has evolved to meet these stringent requirements...

VIEW MORE

Modern manufacturing environments demand exceptional precision in material handling and alignment systems. As production lines become increasingly automated and quality standards continue to rise, manufacturers are seeking advanced feeding solutions ...

VIEW MORE

Manufacturing facilities across various industries rely heavily on automated material handling systems to maintain consistent production flow and operational efficiency. Among these systems, the customized zigzag feeder stands out as a versatile solu...

VIEW MORE

Achieving precise metal sheet leveling requires careful optimization of your multiroller CNC leveling machine settings. These sophisticated industrial systems demand attention to detail across multiple parameters to ensure consistent, high-quality re...

VIEW MORE

Manufacturing operations depend heavily on precision equipment that delivers consistent results day after day. Among the most critical pieces of metalworking machinery are multiroller CNC leveling machines, which ensure flat, stress-free materials es...

VIEW MORE

In modern manufacturing environments, achieving precise flatness and dimensional accuracy in metal components has become increasingly critical for product quality and operational efficiency. The multiroller CNC leveling machine represents a significa...

VIEW MORE

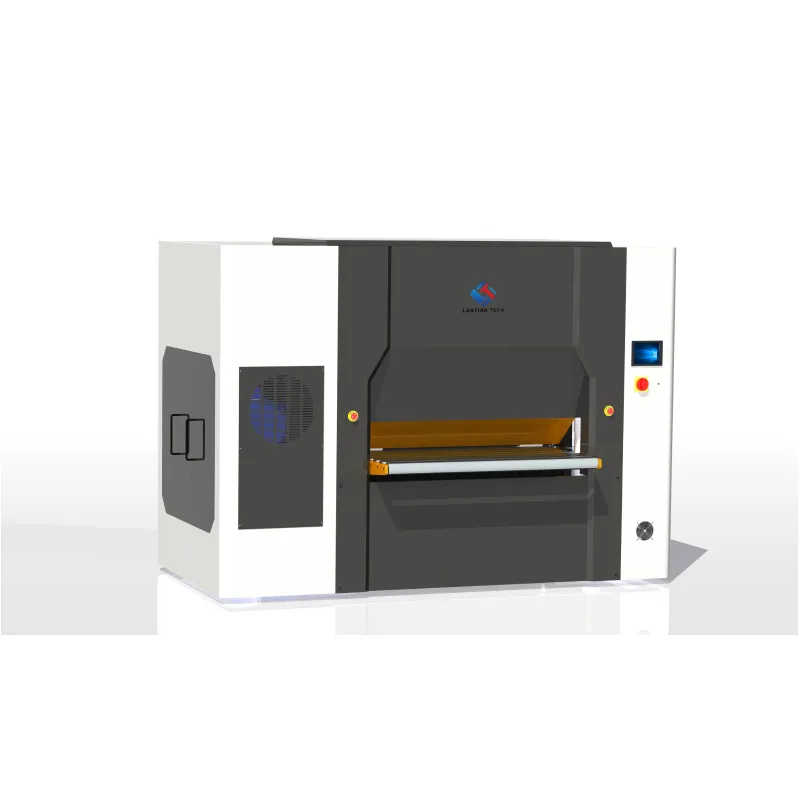

Revolutionizing Steel Fabrication Through Advanced Hydraulic Technology The evolution of structural steel fabrication has been marked by continuous technological advancements, with the hydraulic leveling machine standing at the forefront of modern ma...

VIEW MORE

Maximizing Industrial Leveling Equipment Efficiency Industrial leveling machines play a crucial role in metal fabrication and processing operations. These sophisticated pieces of equipment ensure sheet metal and other materials achieve perfect flatne...

VIEW MORE

Understanding the Critical Role of Precision Leveling in Modern Manufacturing In today's advanced manufacturing landscape, achieving perfect flatness and precision in metal processing has become more crucial than ever. Leveling machines stand at the ...

VIEW MORE

Understanding the Impact of Metal Leveling Technology on Weld Quality Metal fabrication professionals constantly face the challenge of managing welding distortion, a common issue that can compromise the structural integrity and aesthetic appeal of fi...

VIEW MORE