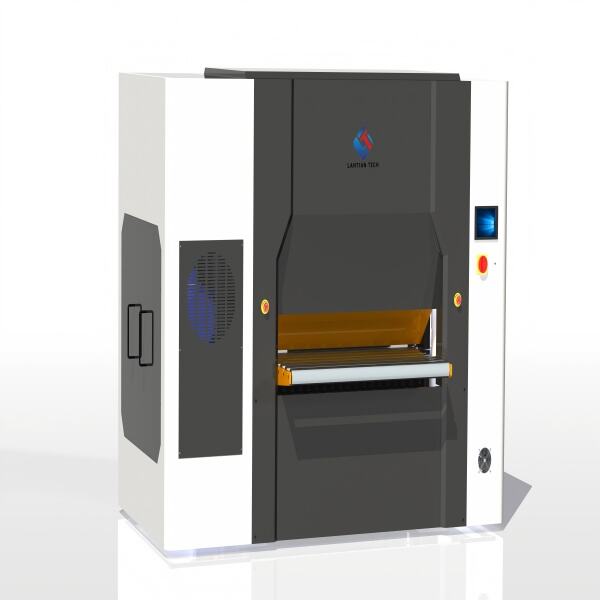

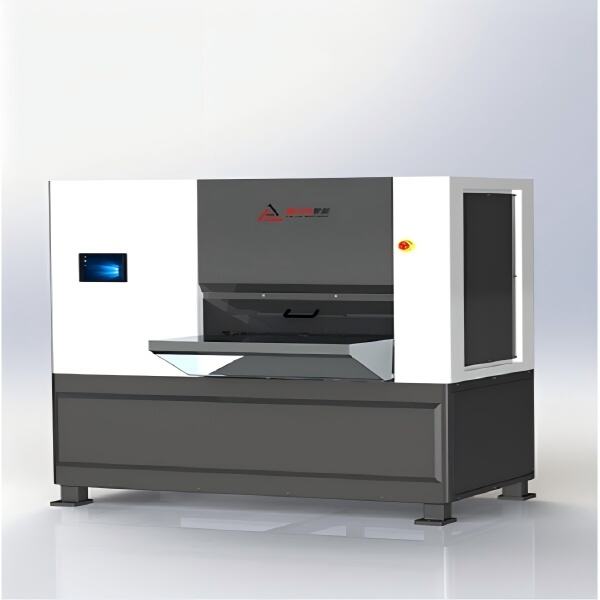

Understanding Modern Sheet Metal Leveling Technology

The evolution of sheet metal processing has reached new heights with the introduction of CNC precision leveling machines. These advanced systems represent a quantum leap in achieving superior flatness in metal sheets, addressing the persistent challenges that manufacturers have faced for decades. By combining sophisticated computer control with precision engineering, these machines are revolutionizing the way industries approach sheet metal processing.

A CNC precision leveling machine utilizes advanced algorithms and mechanical precision to transform distorted or wavy sheet metal into perfectly flat surfaces. This technology has become indispensable across various industries, from automotive manufacturing to aerospace applications, where even minimal deviations from flatness can compromise product quality and performance.

Core Components and Operational Principles

Advanced Roller Configuration

At the heart of a CNC precision leveling machine lies its sophisticated roller system. Multiple work rolls, precisely arranged and individually controlled, apply carefully calculated pressure to the sheet metal. These rolls can be adjusted with microscopic precision, ensuring optimal contact and force distribution across the entire width of the material. The intelligent positioning of these rollers enables the machine to address both minor imperfections and major flatness issues effectively.

The roll configuration typically includes both entry and exit support rolls, along with multiple intermediate work rolls. Each roll's position and pressure can be independently adjusted through the CNC system, allowing for real-time adaptations based on material properties and specific leveling requirements.

Intelligent Control Systems

The control system of a CNC precision leveling machine represents the pinnacle of automation technology. Advanced sensors continuously monitor the leveling process, measuring parameters such as material thickness, hardness, and existing stress patterns. This data feeds into sophisticated algorithms that automatically adjust the machine settings to maintain optimal leveling conditions throughout the entire process.

Real-time feedback loops ensure that any variations in material properties or processing conditions are immediately detected and compensated for, resulting in consistently superior flatness outcomes. The system's ability to make micro-adjustments on the fly prevents common issues such as edge waves and center buckles.

Enhanced Processing Capabilities

Material Versatility

Modern CNC precision leveling machines excel in processing a wide range of materials. From thin aluminum sheets to high-strength steel plates, these systems can handle various metal types and thicknesses with equal precision. The ability to store and recall processing parameters for different materials ensures consistent results across multiple production runs.

The machine's adaptability extends to managing materials with varying yield strengths and surface finishes. This versatility makes it an invaluable asset for manufacturers working with diverse material specifications and end-user requirements.

Production Efficiency Optimization

The implementation of a CNC precision leveling machine significantly enhances production efficiency. These systems can process materials at higher speeds while maintaining superior quality standards. The reduced need for manual adjustments and the elimination of trial-and-error approaches contribute to shorter setup times and increased throughput.

Advanced automation features enable continuous operation with minimal operator intervention, leading to reduced labor costs and improved resource utilization. The precise control over the leveling process also minimizes material waste and the need for rework, further improving operational efficiency.

Quality Assurance and Process Control

Advanced Monitoring Systems

Quality control in modern leveling operations has been transformed by the integration of sophisticated monitoring systems. CNC precision leveling machines incorporate various sensors and measurement devices that continuously track critical parameters throughout the leveling process. These systems can detect and respond to variations in material properties, ensuring consistent quality across entire production runs.

The ability to monitor and record processing data also enables comprehensive quality documentation, meeting the stringent requirements of quality management systems and industry certifications. This data-driven approach to quality control helps manufacturers maintain high standards while providing valuable insights for process optimization.

Precision Documentation and Reporting

The digital nature of CNC precision leveling machines facilitates detailed documentation of all processing parameters and results. Comprehensive reporting capabilities allow manufacturers to track performance metrics, analyze trends, and identify opportunities for improvement. This data becomes invaluable for quality audits, process validation, and continuous improvement initiatives.

Advanced reporting features also enable better traceability, allowing manufacturers to link specific processing parameters with finished product characteristics. This capability is particularly important in industries with strict quality documentation requirements.

Industry Applications and Benefits

Manufacturing Excellence

The impact of CNC precision leveling machines on manufacturing operations is profound. These systems enable manufacturers to achieve unprecedented levels of product quality while maintaining high production efficiency. The ability to consistently produce perfectly flat sheet metal components has opened new possibilities in product design and manufacturing capabilities.

Industries such as automotive, aerospace, and appliance manufacturing have particularly benefited from this technology. The superior flatness achieved through precision leveling translates into improved downstream processing, better assembly fit, and enhanced final product quality.

Cost Reduction and ROI

While the initial investment in a CNC precision leveling machine may be significant, the long-term benefits often justify the cost. Reduced material waste, lower labor requirements, and improved product quality contribute to substantial cost savings over time. The elimination of manual adjustments and reduced need for rework further enhance the return on investment.

The increased production efficiency and capability to handle a wider range of materials also enable manufacturers to expand their service offerings and enter new markets, creating additional revenue opportunities.

Frequently Asked Questions

What is the maximum thickness capacity of a CNC precision leveling machine?

The thickness capacity varies by model, but modern CNC precision leveling machines can typically handle materials ranging from 0.2mm to 25mm thick. Some specialized machines can process even thicker materials, though the exact specifications should be confirmed with the manufacturer for specific applications.

How does a CNC precision leveling machine maintain consistency across different materials?

The machine utilizes advanced sensors and algorithms to continuously monitor material properties and automatically adjust processing parameters. The system stores material-specific processing recipes and can make real-time adjustments based on feedback from multiple monitoring points throughout the leveling process.

What maintenance requirements should be considered for these machines?

Regular maintenance typically includes roller inspection and cleaning, calibration of sensors and control systems, and lubrication of moving parts. The machine's software also requires periodic updates to ensure optimal performance and access to the latest features. Most manufacturers recommend scheduled preventive maintenance to maximize machine longevity and maintain processing accuracy.