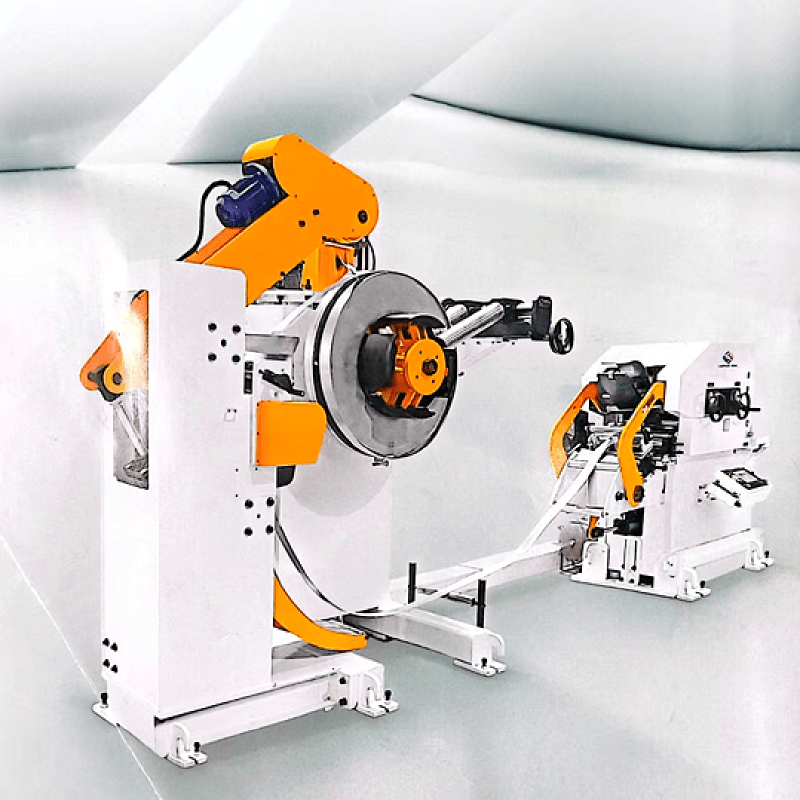

NCLT70A 6.0mm Thick Material

Product Features:

Applicable to ordinary low-carbon steel, galvanized sheet, thick plate, stainless steel and othematerials;

The working roller is made of bearing steel hardened and chrome-plated, with a hardness ofHRC60±2;

A full set of Siemens servo system is used to ensure high-precision feeding;

Humanized design, combined with safety protection system, is easy for personnel to operate;

This model adopts modular design, and the corresponding configuration can be purchased according to actual needs.

- Overview

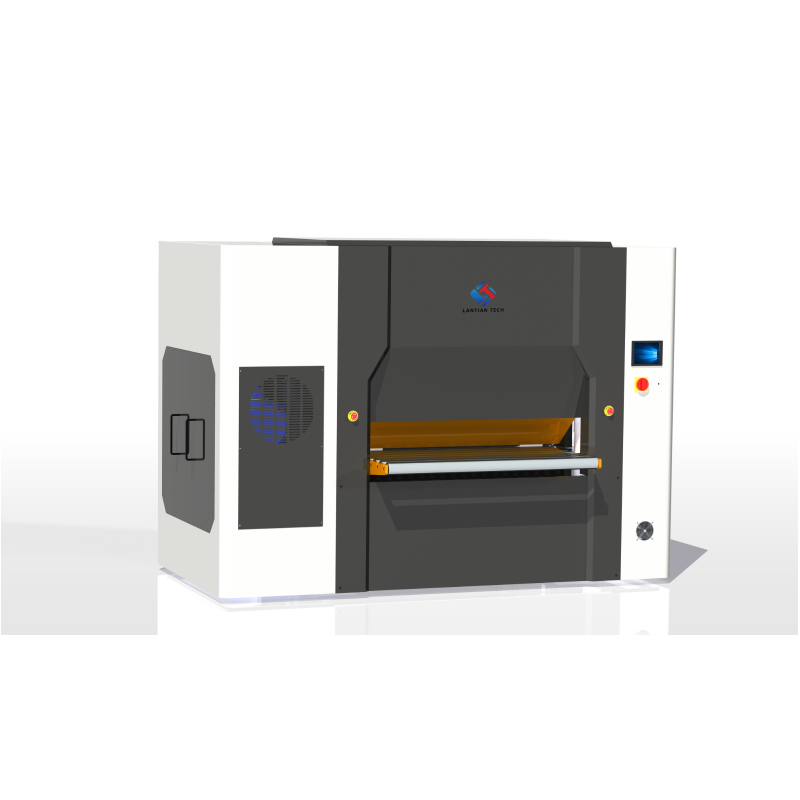

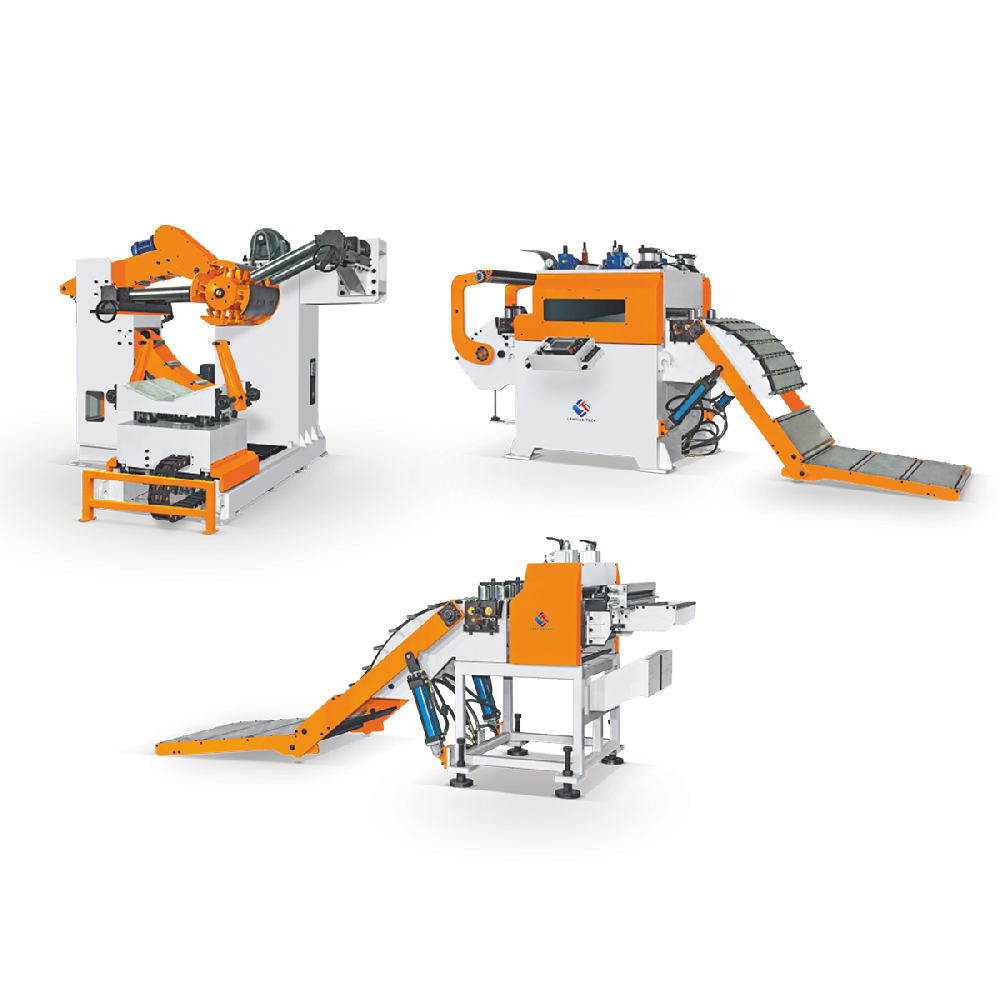

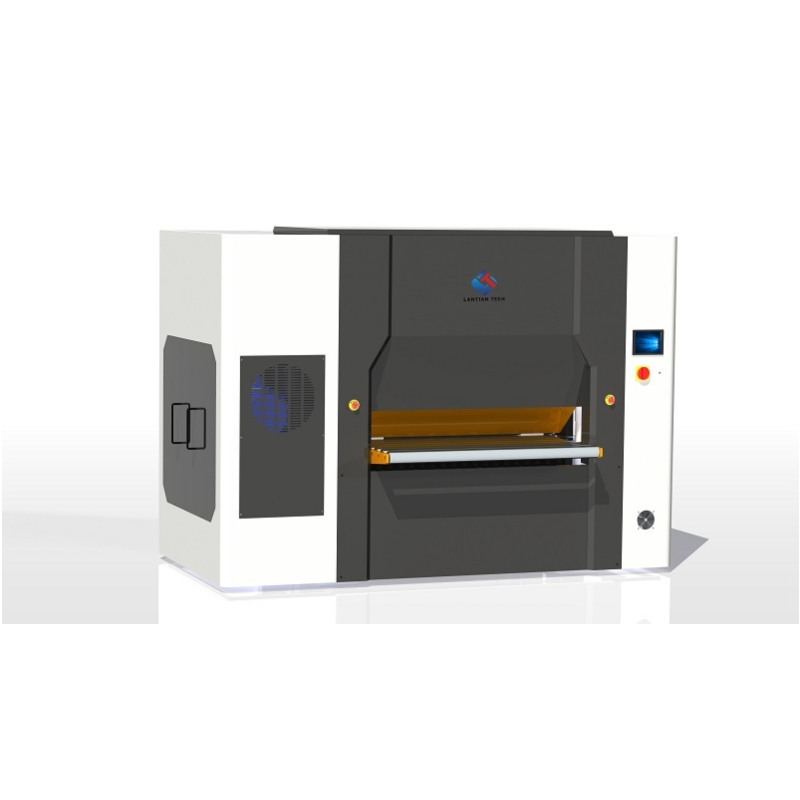

- Recommended Products

| NCLT70A 6.0mm Thick Material | ||||||

| Technical Parameter | ||||||

| Model | NCLT70A-400 | NCLT70A-600 | NCLT70A-800 | NCLT70A-1000 | NCLT70A-1300 | |

| Decoiler parameter | Coil I.D | 508/610 | ||||

| Max Coil 0.D | 1500 | |||||

| Max Coil weight | 5000 8000 12000 | |||||

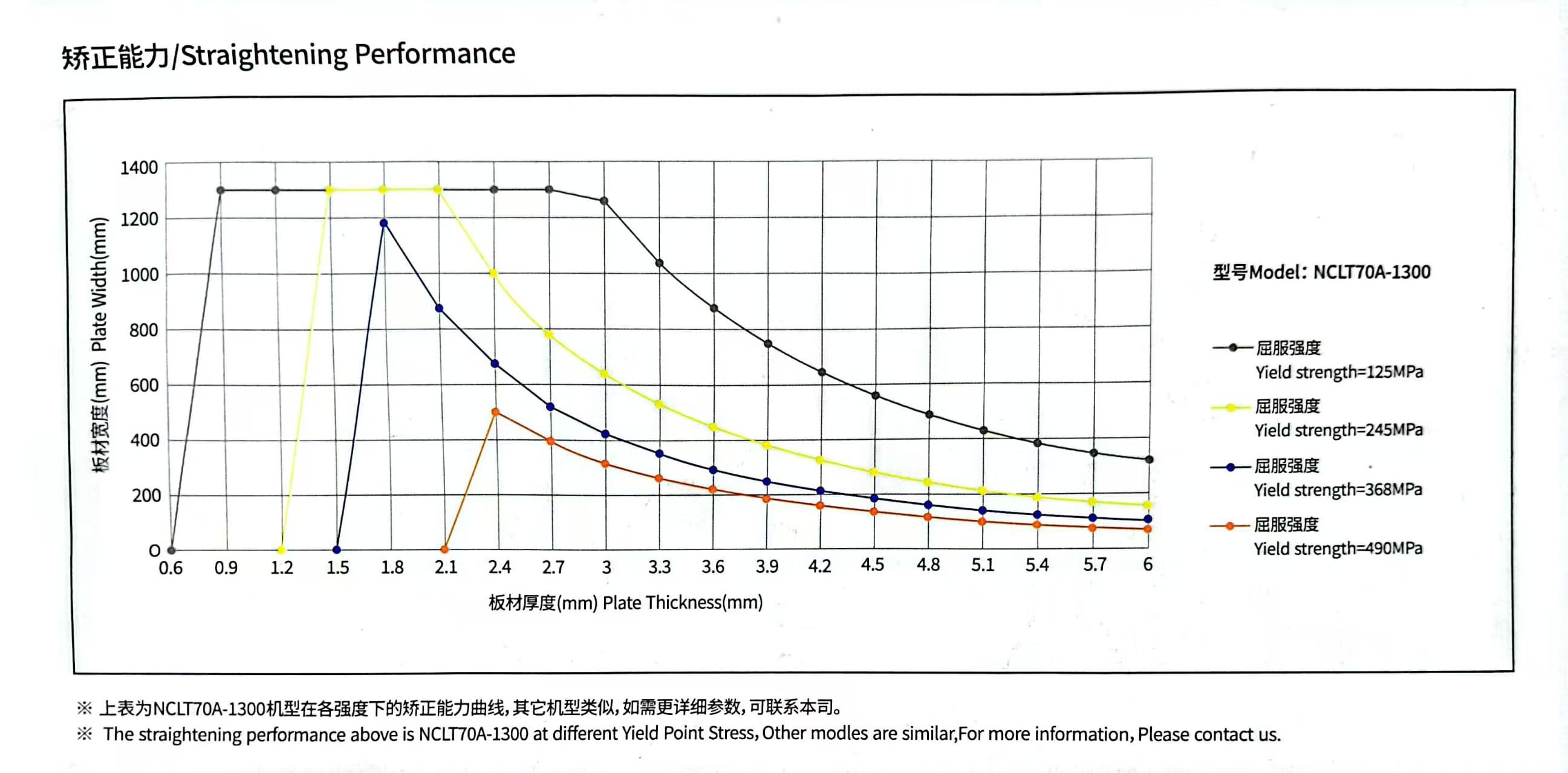

| Straightener Parameter | Thickness of Material | 0.6-6.0 | ||||

| width of Material | 70-400 | 70-600 | 70-800 | 70-1000 | 70-1300 | |

| Max Yield Point Stress | 490 | |||||

| Max Tensile strength | 780 | |||||

| The Optimal Thickness Range | 1.0-3.0 | |||||

| Straightening Roller Diameter | 70 | |||||

| Straightening Roller | Up4/Down3 | |||||

| Feeder Parameter | Feeding Speed | 16 | ||||

| Max Feeding Length | 0-9999.99 | |||||

| Feeding Level | (1200土100)According to Customer's Requirements | |||||

| System Parameter | Decoiling motor | 2.2 | 3.7 | 5.5 | ||

| Servo motor | 5.5 7.5 | |||||

| Power Supply | (380V/50HZ) 3-Phrase 380V/50Hz or as customer request | |||||

| Air supply | 0.4-0.6 MPa,1.0³/min | |||||

※In the table above, The Optimal Thickness Range is caculated at Yield Point Stress 245N/mm²(tensile strength 392N/mm²)

|

|

Standard accessory: |

0ption accessory: ※ Special configurations can also be made by our company |

|

|

|

|

|

|

|

|

| Strong conveying force | Wide adaptability | High cost performance | Simple structure | The job is stable | Flexible layout | Safe and reliable | Easy to maintain |