NCLT120 materiał 15.0mm nadzwyczaj gruby

Funkcje:

Stosowany do zwykłej blachy stalowej niskowęglowej, blachy ocynkowanej, blachy extra-grubej, stali nierdzewnej i innych materiałów;

Walec roboczy wykonany jest ze stali łożyskowej utwardzonej i chromowanej, o twardości HRC60±2;

Elektryczna regulacja ilości korekty zastępuje ręczną regulację pokrętłem, co ułatwia obsługę;

Zastosowano pełen system serwonapędowy marki Siemens, zapewniający precyzyjne dozowanie materiału;

Nowoczesny projekt, w połączeniu z systemem zabezpieczeń, umożliwia łatwe obsługiwania przez personel;

Zaplanowane specjalnie do cienkich blach, łatwe do podawania, mocna konstrukcja głowicy, doskonały efekt wygładzania;

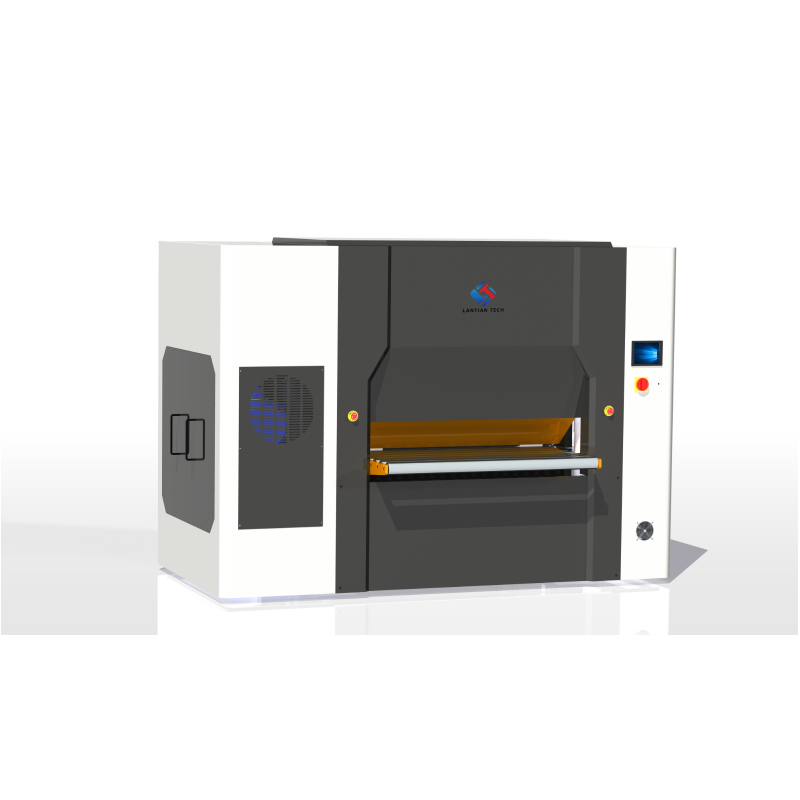

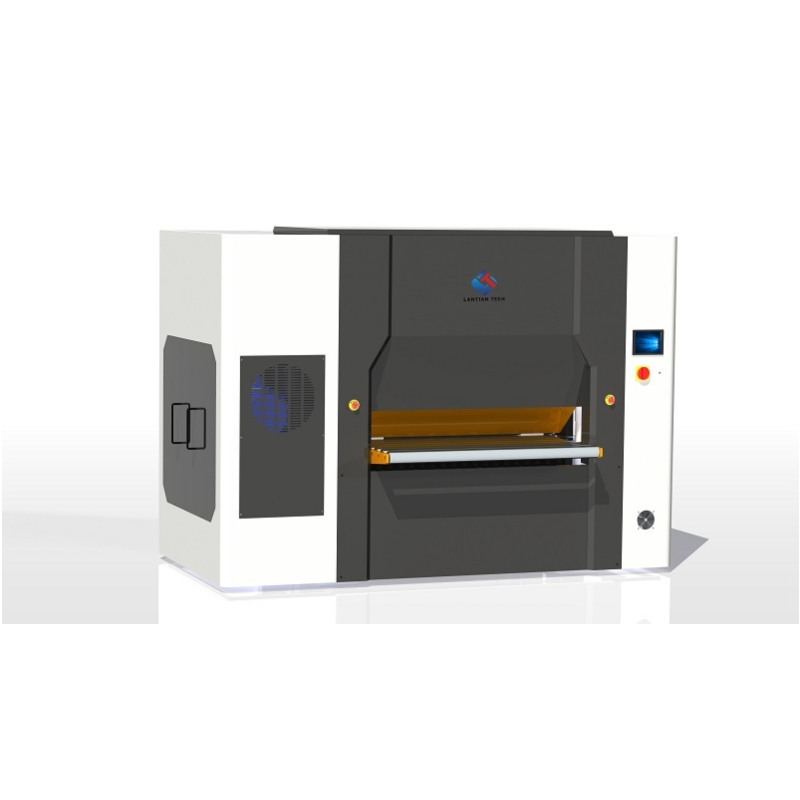

- Przegląd

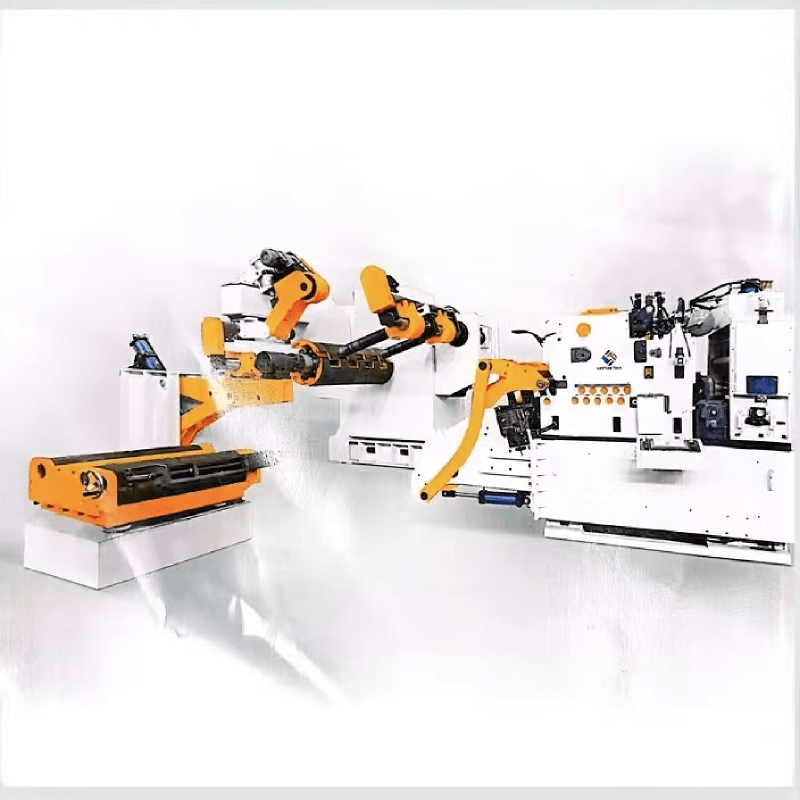

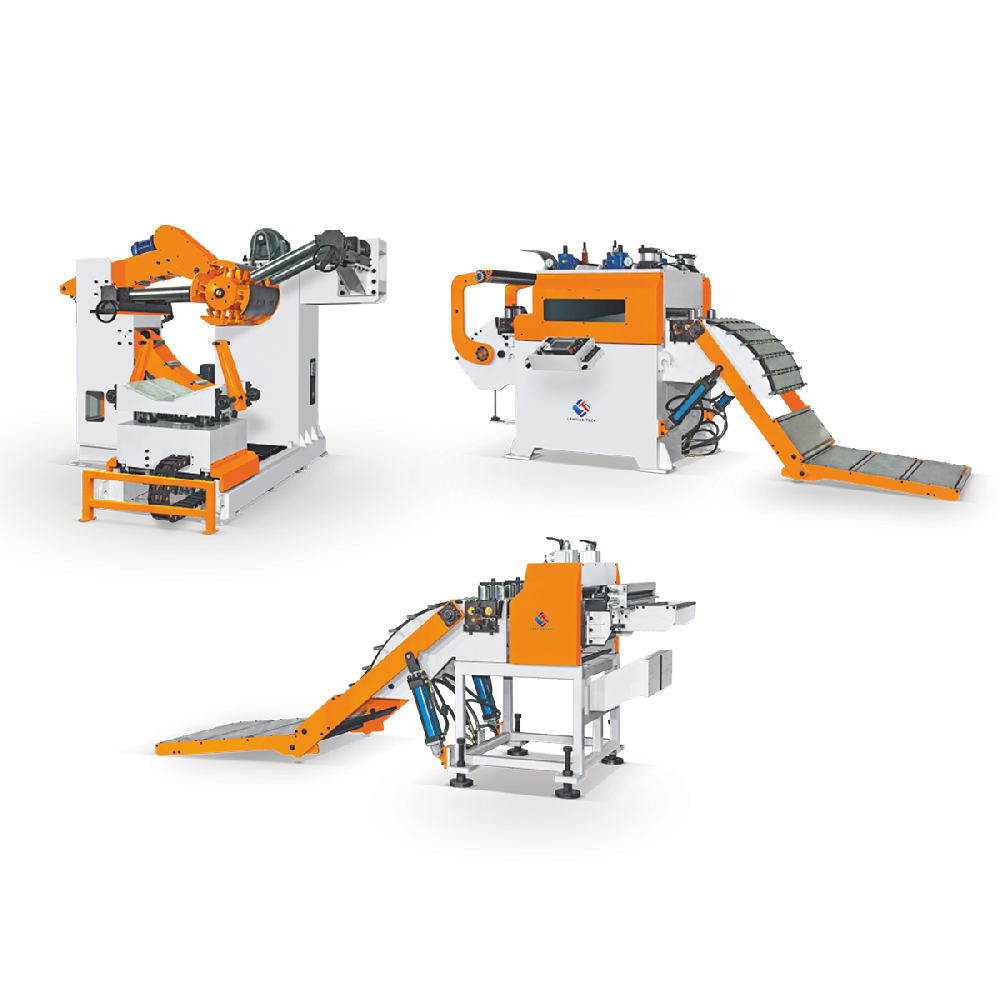

- Polecane produkty

| NCLT120 materiał 15.0mm nadzwyczaj gruby | |||||

| Parametry techniczne | |||||

| Model | NCLT120-400 | NCLT120-600 | NCLT120-800 | NCLT120-1000 | |

| Parametr rozdrabniacza | Średnica wewnętrzną cewnika | 508/610 | |||

| Maks. średnica cewnika | 1600 | ||||

| Maksymalna waga zwoju | 8000 12000 | ||||

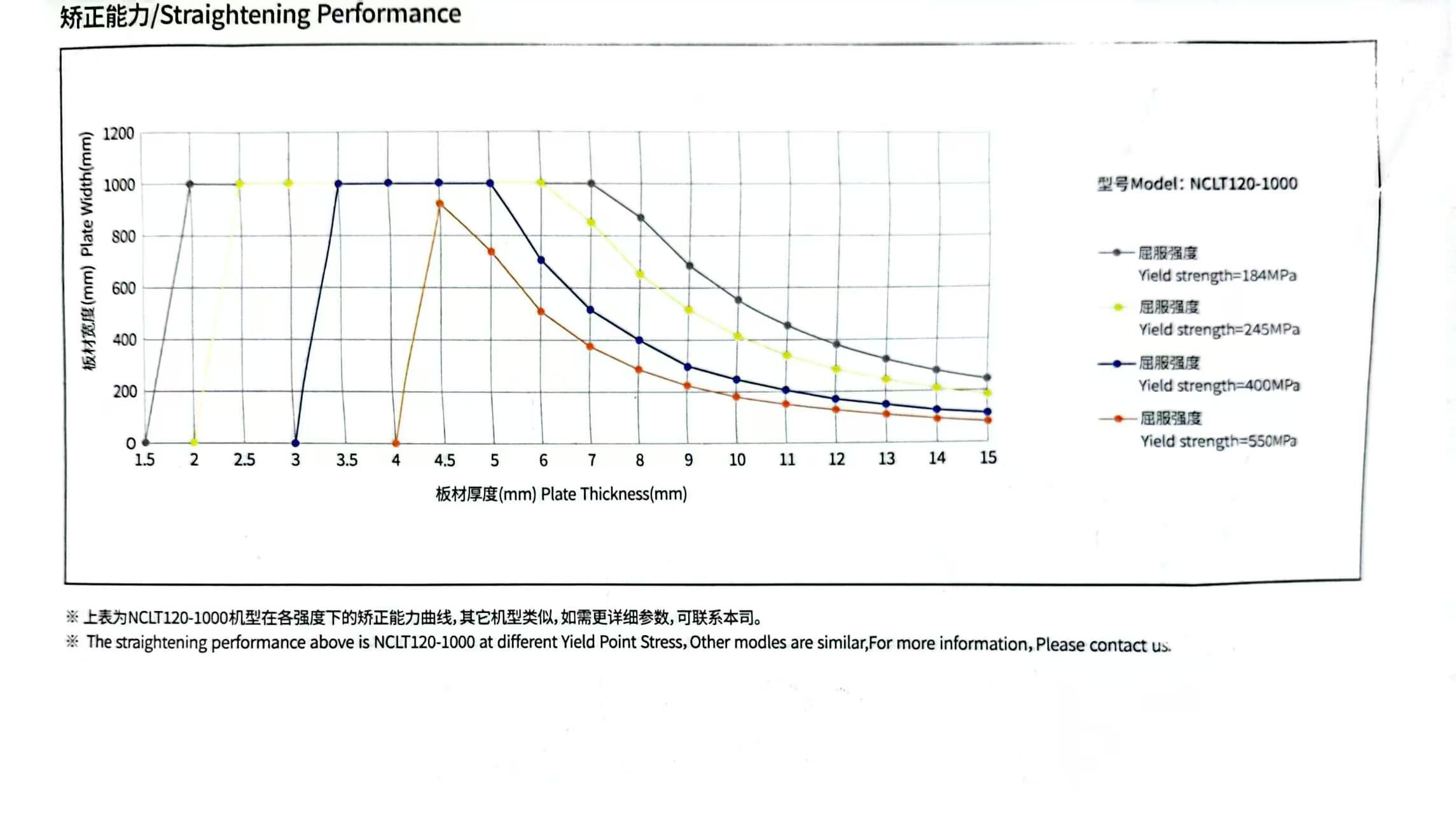

| Parametr prostownika | Grubość materiału | 1.5-15.0 | |||

| szerokość materiału | 100-400 | 100-600 | 100-800 | 100-1000 | |

| Maksymalne naprężenie przy granicy plastyczności | 550 | ||||

| Maksymalna wytrzymałość na rozciąganie | 880 | ||||

| Optymalny zakres grubości | 1.8-6.0 | ||||

| Średnica wałka do wyprostowywania | 120 | ||||

| Walec wyprostowujący | Up4/Down3 | ||||

| Parametr podajnika | Prędkość podawania | 16 | |||

| Maksymalna długość podawania | 0-9999.99 | ||||

| Poziom zasilania | (1200±100) Zgodnie z wymaganiami klienta | ||||

| Parametr systemu | Silnik rozdrabniarki | 5.5 | 7.5 | ||

| Serwo silnik | 15 | 22 | |||

| Zasilanie | (380V/50HZ)3-fazowy 380V/50Hz lub zgodnie z życzeniem klienta | ||||

| Zasilanie powietrzem | 0,4-0,6 MPa, 1,6³/min | ||||

※W powyższej tabeli Zakres Optymalnej Grubości jest obliczany przy naprężeniu plastycznym 245N/mm² (wytrzymałość na rozciąganie 392N/mm²)

|

|

Standardowe akcesoria: Automatyczne/ręczne przełączanie System sterowania łukiem materiałowym za pomocą fotokomórki Układ hamulcowy pneumatyczny z tarczami Elektryczna regulacja wysokości linii zasilania Fotoelektryczne wykrywanie materiału końcowego Ekran dotykowy Rozszerzanie i zwężanie hydrauliczne Wózek ładujący typu bęben Napędzany ramię dociskowe Ramię podtrzymujące materiał Podwójne elektryczne ograniczniki ruchu Zespół zdejmowania materiału Głowica dociskająca materiał Wyrównujące urządzenie prowadzące Układ kierujący wylotowy do wypoziomowania Elektryczna regulacja daty regulacji Data regulacji - wskaźnik cyfrowy Data regulacji - zapis i odczyt cyfrowy Określony kolor lakieru |

opcjonalny akcesorium: ※ Specjalne konfiguracje mogą również zostać wykonane przez naszą firmę |

|

|

|

|

|

|

|

|

| Silna siła transportowa | Szeroka adaptowalność | Wysokie koszty działania | Prosta konstrukcja | Praca jest stabilna | Elastyczny Układ | Bezpieczne i niezawodne | Łatwe w utrzymaniu |