NCLT120 15.0mm Super silný materiál

Vlastnosti:

Použitelné pro běžnou nízkouhlíkovou ocel, pozinkovaný plech, extra silný plech, nerezovou ocel a jiné materiály;

Pracovní válec je vyroben z ložiskové oceli, kalené a potažené chromem, s tvrdostí HRC60±2;

Elektrické nastavení korekčního množství nahrazuje manuální nastavení klikou, čímž se zjednodušuje ovládání;

Plný set servosystému značky Siemens zajišťuje vysokou přesnost přívodu;

Uživatelsky přívětivý design v kombinaci se systémem ochrany před úrazem usnadňuje obsluhu personálu;

Speciálně navrženo pro extra silné cívky plechu, snadné nakládání, robustní konstrukce hlavy a vynikající vyrovnávací účinek;

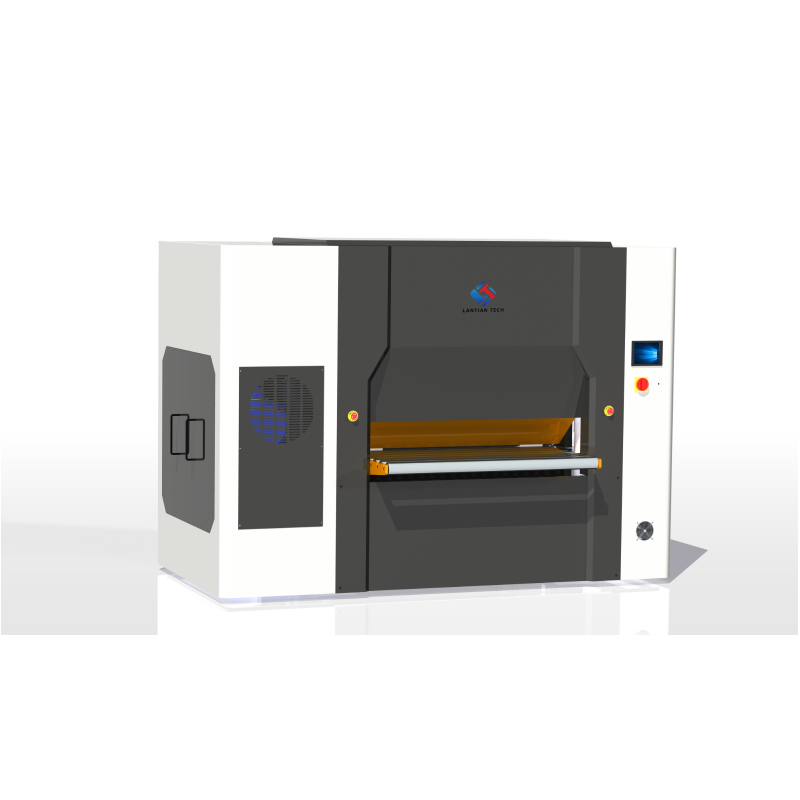

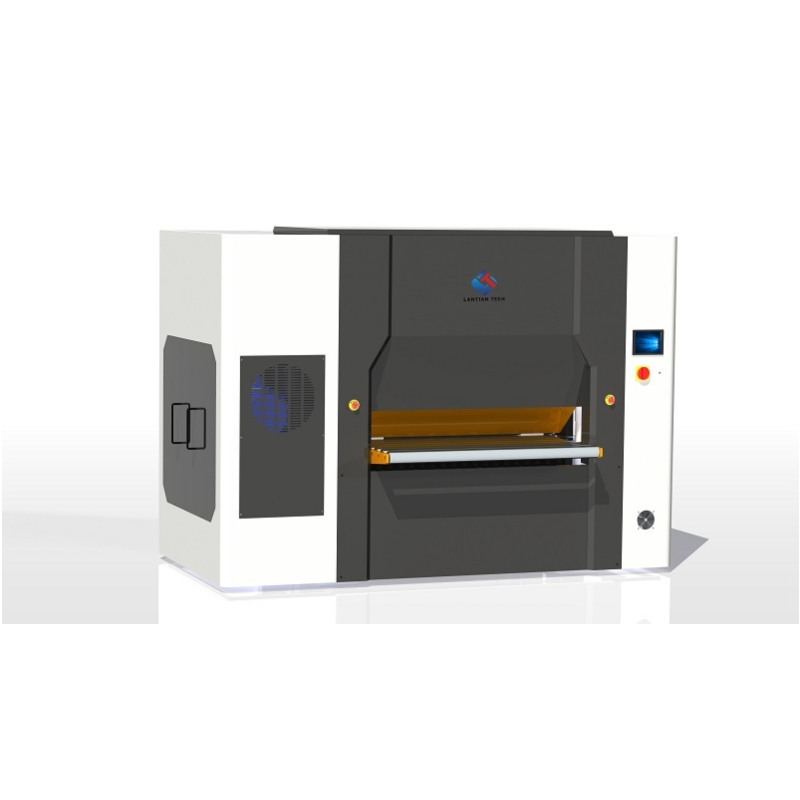

- Přehled

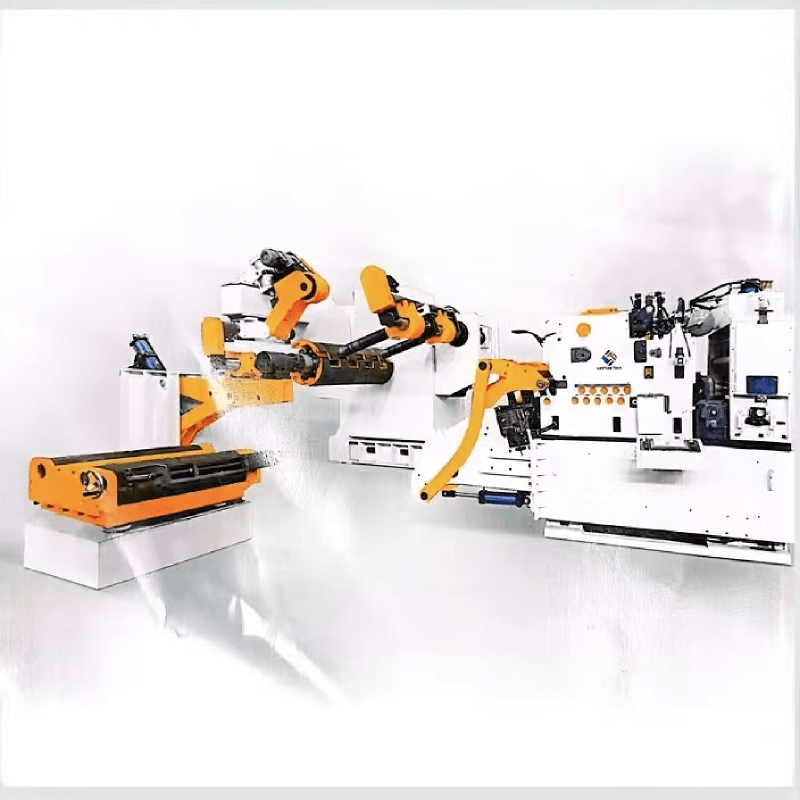

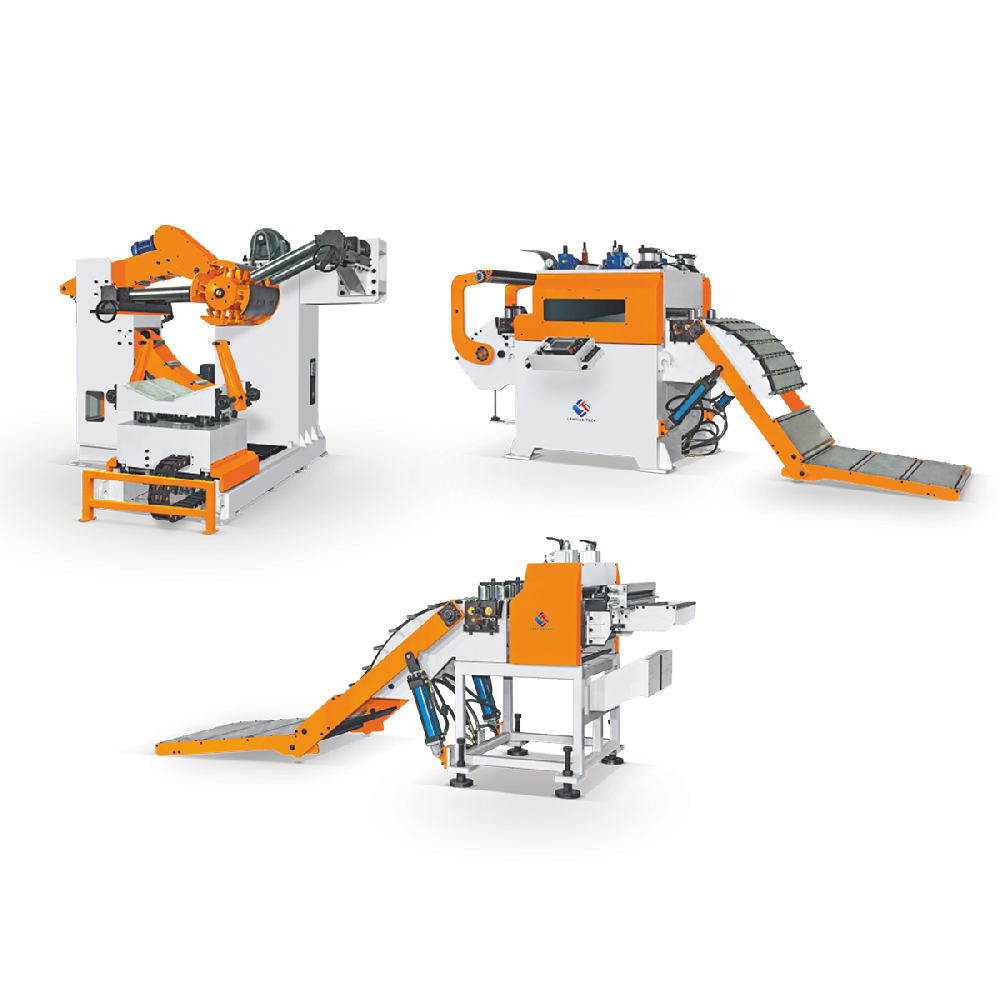

- Doporučené produkty

| NCLT120 15.0mm Super silný materiál | |||||

| Technický parametr | |||||

| Model | NCLT120-400 | NCLT120-600 | NCLT120-800 | NCLT120-1000 | |

| Parametr rozvinovacího zařízení | Vnitřní průměr cívky | 508/610 | |||

| Maximální vnější průměr cívky | 1600 | ||||

| Maximální hmotnost cívky | 8000 12000 | ||||

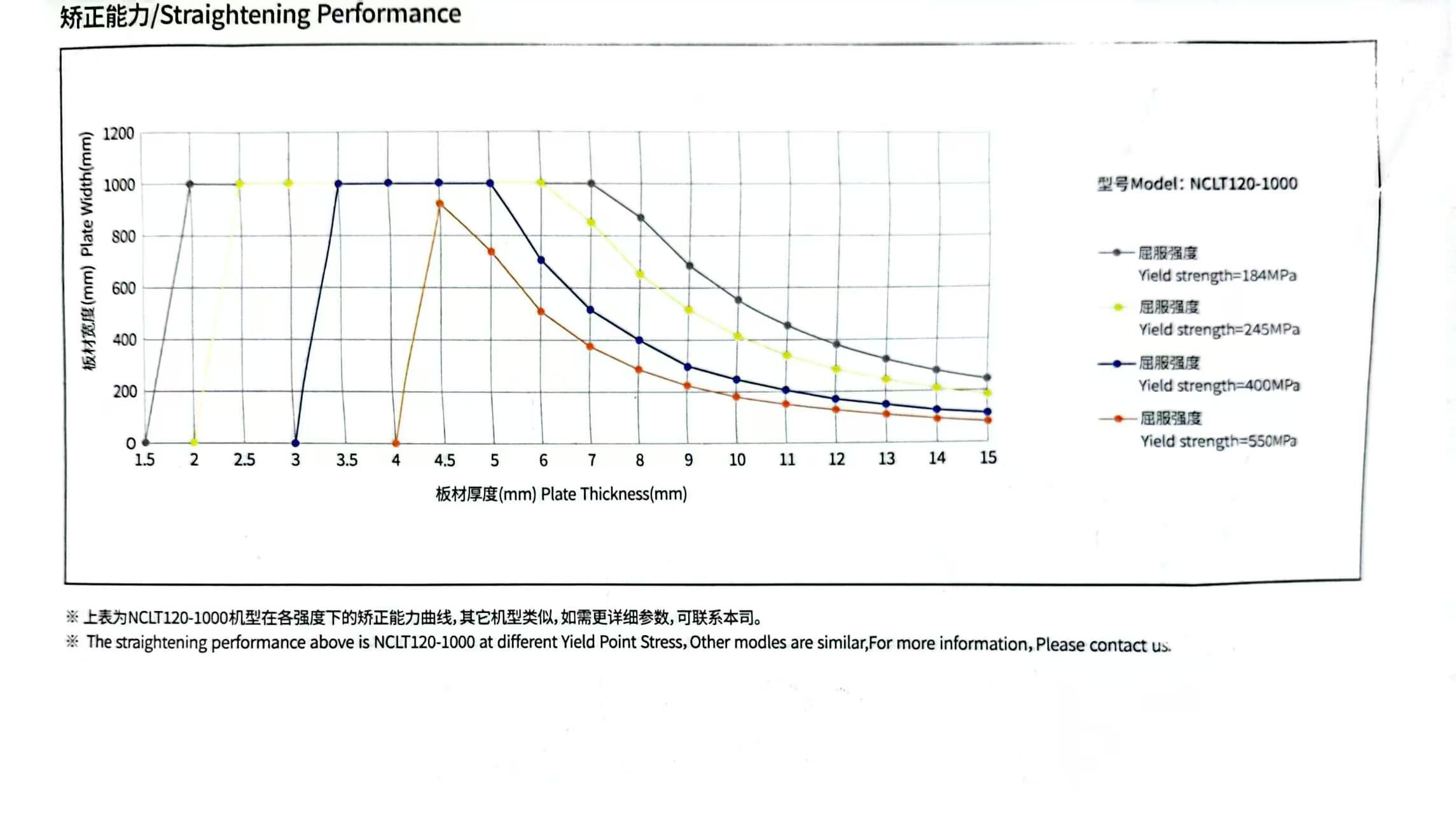

| Parametr rovnacího zařízení | Tloušťka materiálu | 1.5-15.0 | |||

| šířka materiálu | 100-400 | 100-600 | 100-800 | 100-1000 | |

| Mezní tahové napětí | 550 | ||||

| Maximální pevnost v tahu | 880 | ||||

| Optimální rozsah tloušťky | 1.8-6.0 | ||||

| Průměr rovnacích válců | 120 | ||||

| Výpravný válec | Nahoru4/Dolů3 | ||||

| Parametr podávače | Rychlost podávání | 16 | |||

| Maximální délka vedení | 0-9999.99 | ||||

| Úroveň podávání | (1200±100) Dle požadavků zákazníka | ||||

| Systémový parametr | Rozvinovací motor | 5.5 | 7.5 | ||

| Servomotor | 15 | 22 | |||

| Napájení | (380V/50Hz) Trojfázový 380V/50Hz nebo dle požadavku zákazníka | ||||

| Vzduchová dodávka | 0,4-0,6 MPa, 1,6³/min | ||||

※Ve výše uvedené tabulce je optimální rozsah tloušťky vypočten pro mez kluzu 245 N/mm² (pevnost v tahu 392 N/mm²)

|

|

Standardní příslušenství: Automatické/ruční přepínání Systém řízení oblouku materiálu pomocí fotoelektrického snímání Zařízení s pneumatickou kotoučovou brzdou Elektrické nastavení výšky přívodního potrubí Fotobuňkové snímání konečného materiálu Dotyková obrazovka Hydraulické roztažení a smrštění Válcový nakládací vozík Poháněná přitlačovací páka Podpůrná páka materiálu Dvojitá elektrická dorazová páka Skládací zařízení pro přívod materiálu Zařízení přítlačné hlavy materiálu Zařízení vstupního vedení pro vyrovnání Zarovnávací výsuvné vodítko Elektrické nastavení datumu úpravy Datum úpravy – číselné zobrazení Datum úpravy – číselné ukládání a volání Specifikovaná barva nátěru |

0ption příslušenství: ※ Speciální konfigurace mohou být také vytvořeny naší společností |

|

|

|

|

|

|

|

|

| Silná dopravní síla | Široká přizpůsobivost | Vysoká cena výkonu | Jednoduchá konstrukce | Práce je stabilní | Průběžná rozvržení | BEZPEČNÉ A SPOLEHLIVÉ | Snadno udržovatelné |