NCLT90P 4.5mm High Strength Material

Features:

Suitable for medium and high strength plates, stainless steel and other materials;

The working roller is made of bearing steel hardened and chrome plated, with a hardness of HRC60±2;

The electric adjustment of the correction amount replaces the manual handle adjustment method, making the operation easier;

A full set of Siemens servo systems are used to ensure high-precision feeding;

Humanized design, combined with a safety protection system, is convenient for personnel to operate;

The frame-type head structure designed specifically for high-strength plates greatly enhances the rigidity of the upper and lower rollers to ensure that the straightening meets the standards;

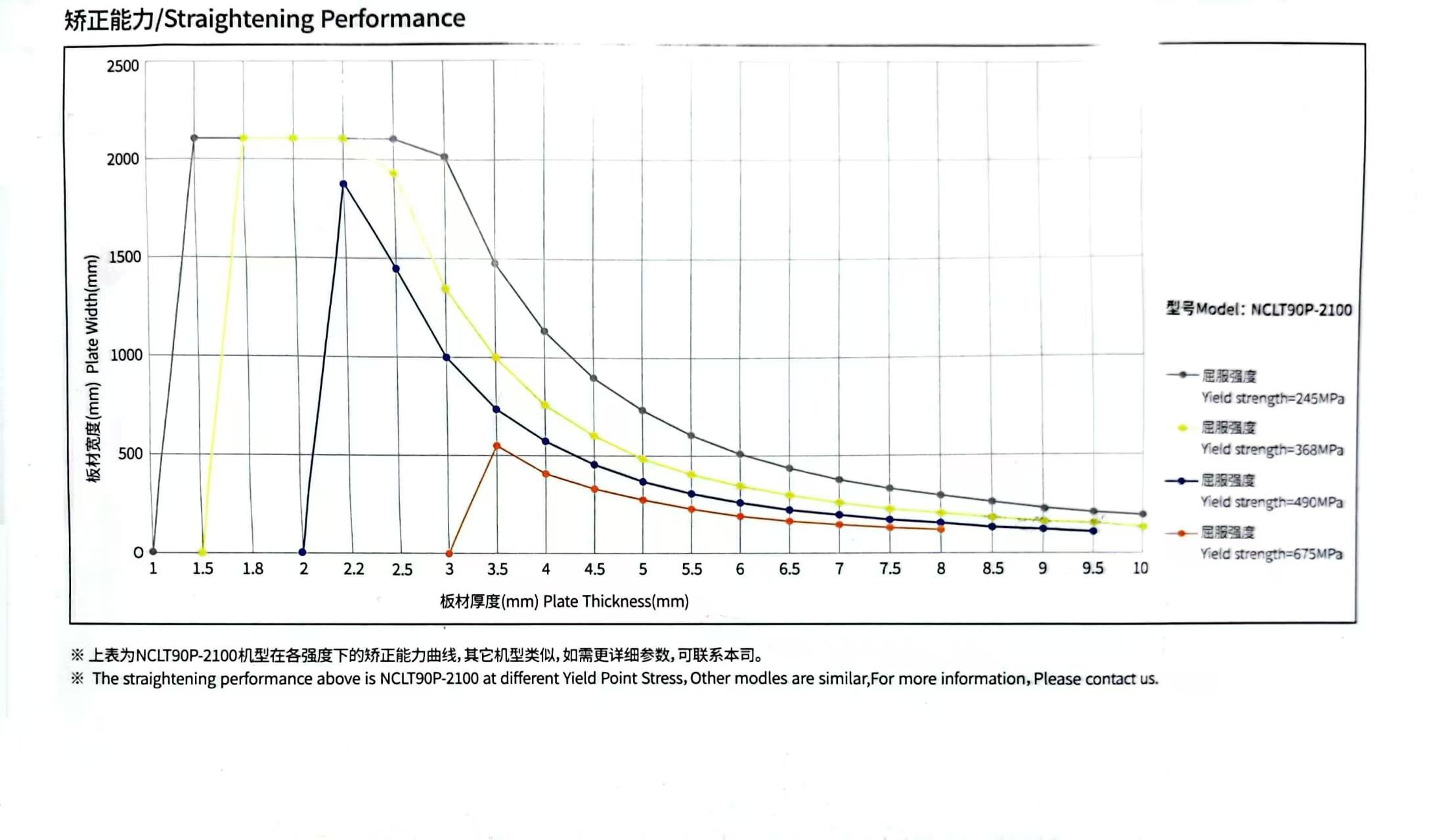

This model is particularly suitable for materials with a yield strength of 675N/mm² (corresponding to a tensile strength of 1080N/mm²) and a range of 1.0~4.5mm;

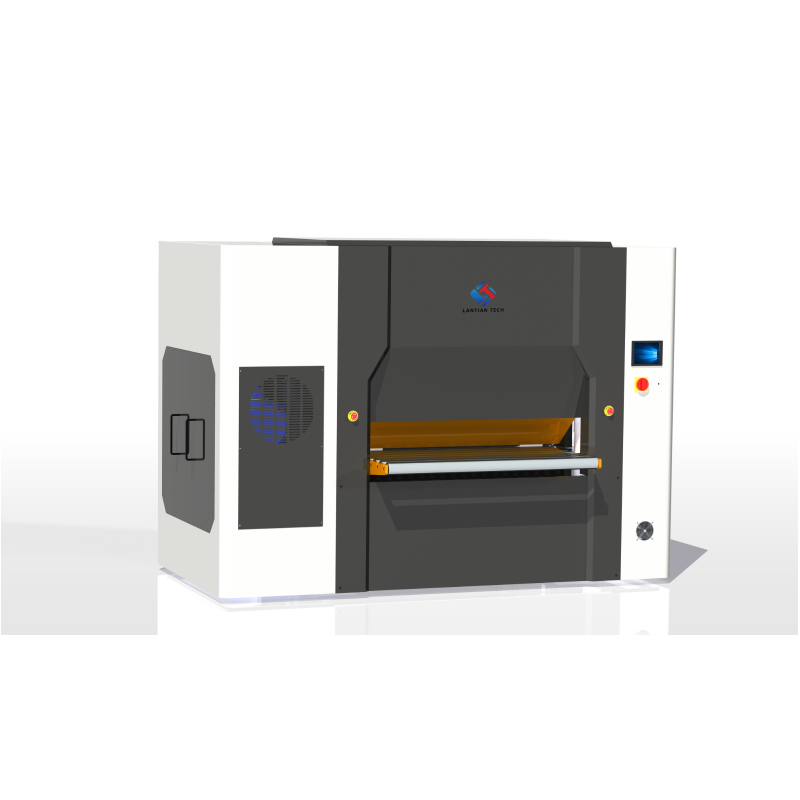

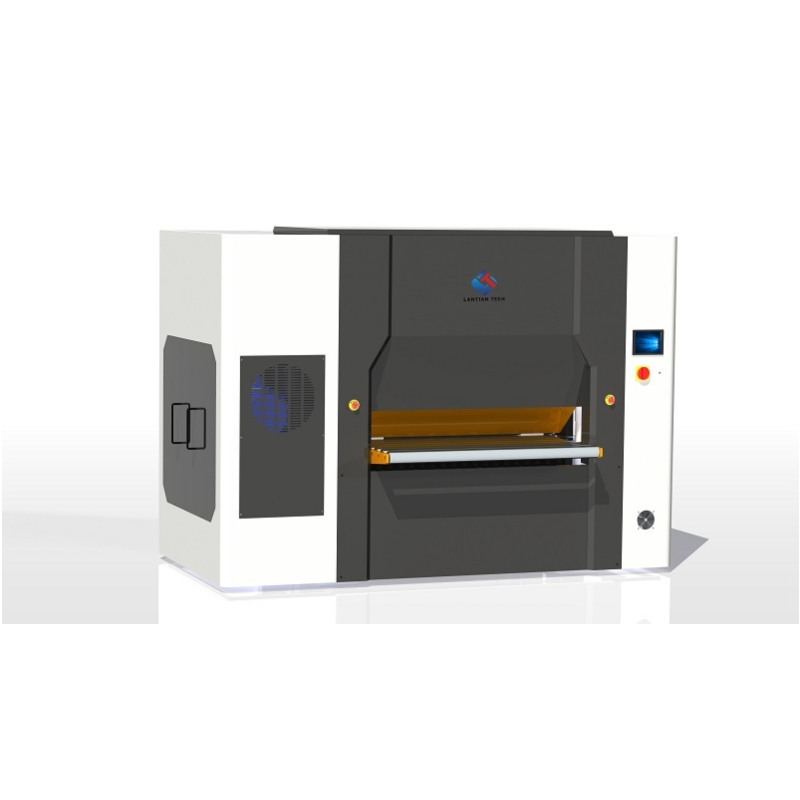

- Overview

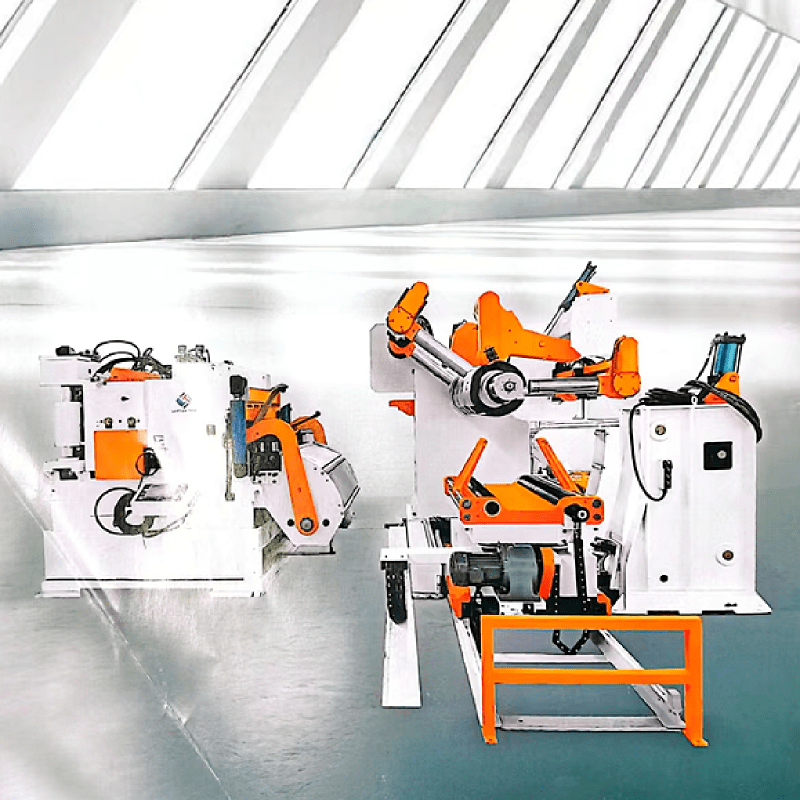

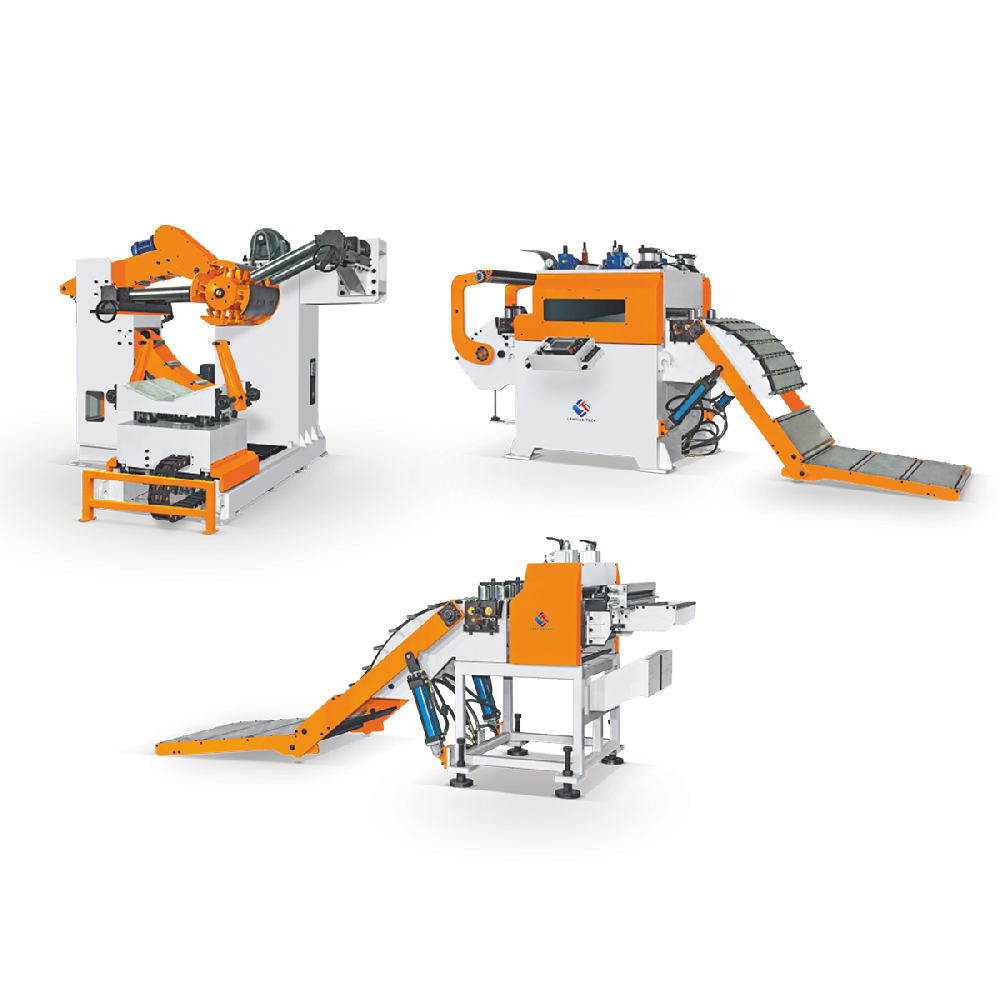

- Recommended Products

| NCLT90P 4.5mm High Strength Material | ||||||||

| Technical Parameter | ||||||||

| Model | NCLT90P-600 | NCLT90P-800 | NCLT90P-1000 | NCLT90P-1300 | NCLT90P-1600 | NCLT90P-1800 | NCLT90P-2100 | |

| Decoiler parameter | Coil I.D | 508/610 | ||||||

| Max Coil 0.D | 1500 | |||||||

| Max Coil weight | 5000 8000 12000 15000 | |||||||

| Straightener Parameter | Thickness of Material | 1.0-10.0 | ||||||

| width of Material | 100-600 | 100-800 | 10-1000 | 100-1300 | 100-1600 | 100-1800 | 100-2100 | |

| Max Yield Point Stress | 675 | |||||||

| Max Tensile strength | 1080 | |||||||

| The Optimal Thickness Range | 1.0-4.5 | |||||||

| Straightening Roller Diameter | 90 | |||||||

| Straightening Roller | Up5/Down4 | |||||||

| Feeder Parameter | Feeding Speed | 16 | ||||||

| Max Feeding Length | 0-9999.99 | |||||||

| Feeding Level | (1200土100)According to Customer's Requirements | |||||||

| System Parameter | Decoiling motor | 2.2 | 3.7 | 7.5 | 11 | |||

| Servo motor | 15 22 30 | |||||||

| Power Supply | (380V/50HZ)3-Phrase 380V/50Hz or as customer request | |||||||

| Air supply | 0.4-0.6 MPa,1.6³/min | |||||||

※In the table above, The Optimal Thickness Range is caculated at Yield Point Stress 245N/mm²(tensile strength 392N/mm²)

|

|

Standard accessory: Automatic/manual switching Material arc photoelectric control system Air pressure disc brake device Feeding line height electric adjustment End material photoelectric detection Touch screen Hydraulic expansion and contraction UnPowered pressing arm Leveling inlet guide device Manual adjustment of Adjustment date Dial display of Adjustment date Specified paint color |

0ption accessory: loading trolley Material support arm Limiting arm Automatic oil feeder Hydraulic shear Head can be lifted Working rollers up 6 down 5 Adjustment date electric adjustment Adjustment date numerical display Adjustment date numerical storage and call ※ Special configurations can also be made by our company |

|

|

|

|

|

|

|

|

| Strong conveying force | Wide adaptability | High cost performance | Simple structure | The job is stable | Flexible layout | Safe and reliable | Easy to maintain |