NCLT90P 4.5mm Bahan Kekuatan Tinggi

Ciri-ciri:

Sesuai untuk kepingan berkekuatan sederhana hingga tinggi, keluli tahan karat dan bahan-bahan lain;

Silinder kerja diperbuat daripada keluli bantalan yang telah dikeraskan dan disalut krom, dengan kekerasan sebesar HRC60±2;

Pelan pengimbasan elektrik menggantikan kaedah pelan pengimbasan secara manual, menjadikan operasi lebih mudah;

Satu set penuh sistem servis Siemens digunakan bagi memastikan suapan yang berketepatan tinggi;

Reka bentuk yang mesra pengguna, dikombinasikan dengan sistem perlindungan keselamatan, memudahkan operasi oleh kakitangan;

Struktur kepala berbentuk rangka yang direka khas untuk kepingan berkekuatan tinggi meningkatkan kekakuan silinder atas dan bawah bagi memastikan rataan memenuhi piawaian;

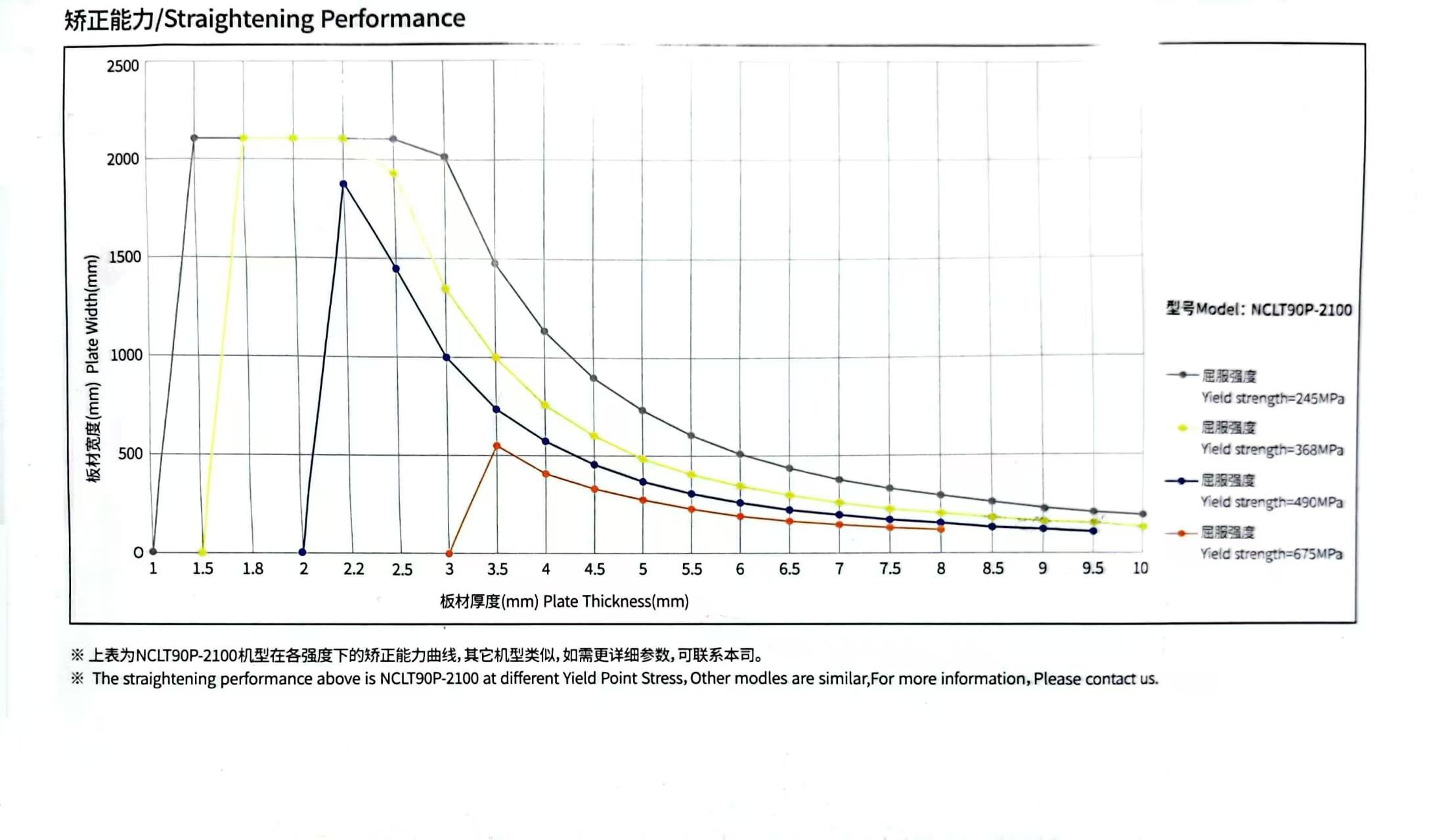

Model ini sangat sesuai untuk bahan dengan kekuatan alah 675N/mm² (sepadan dengan kekuatan tegangan 1080N/mm²) dan julat 1.0~4.5mm;

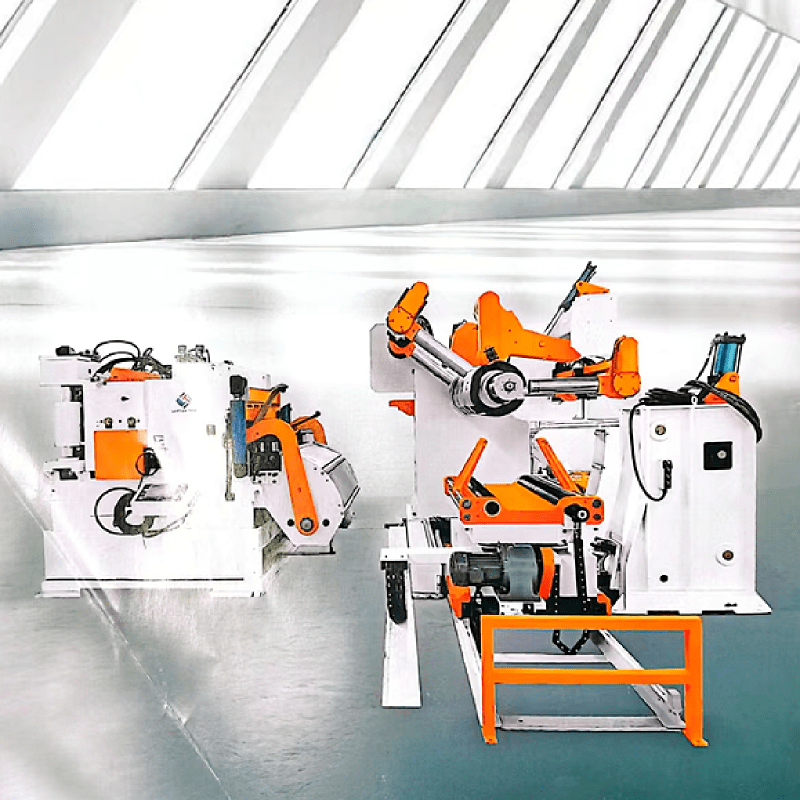

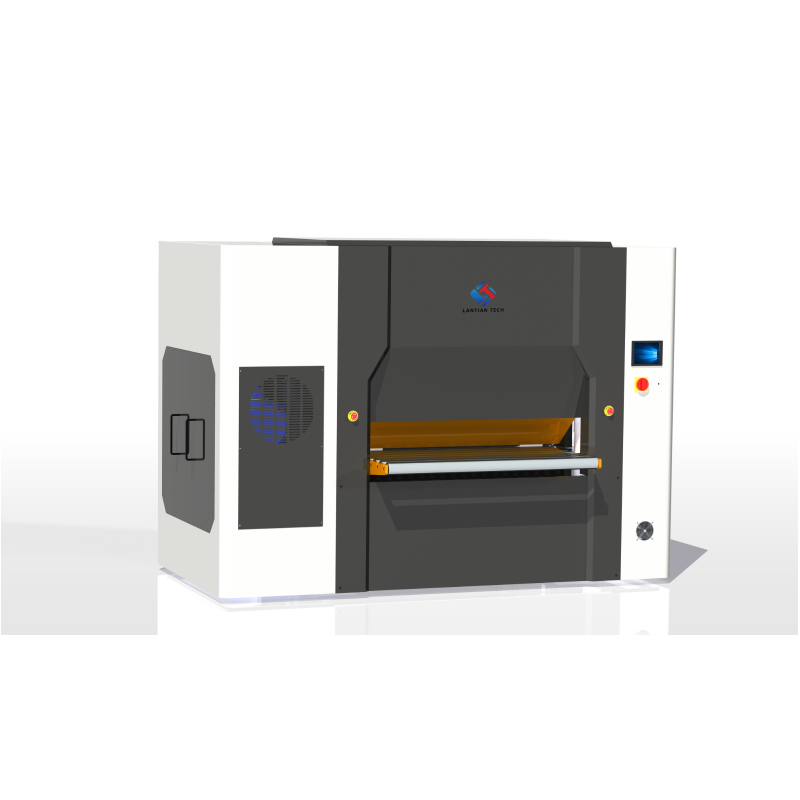

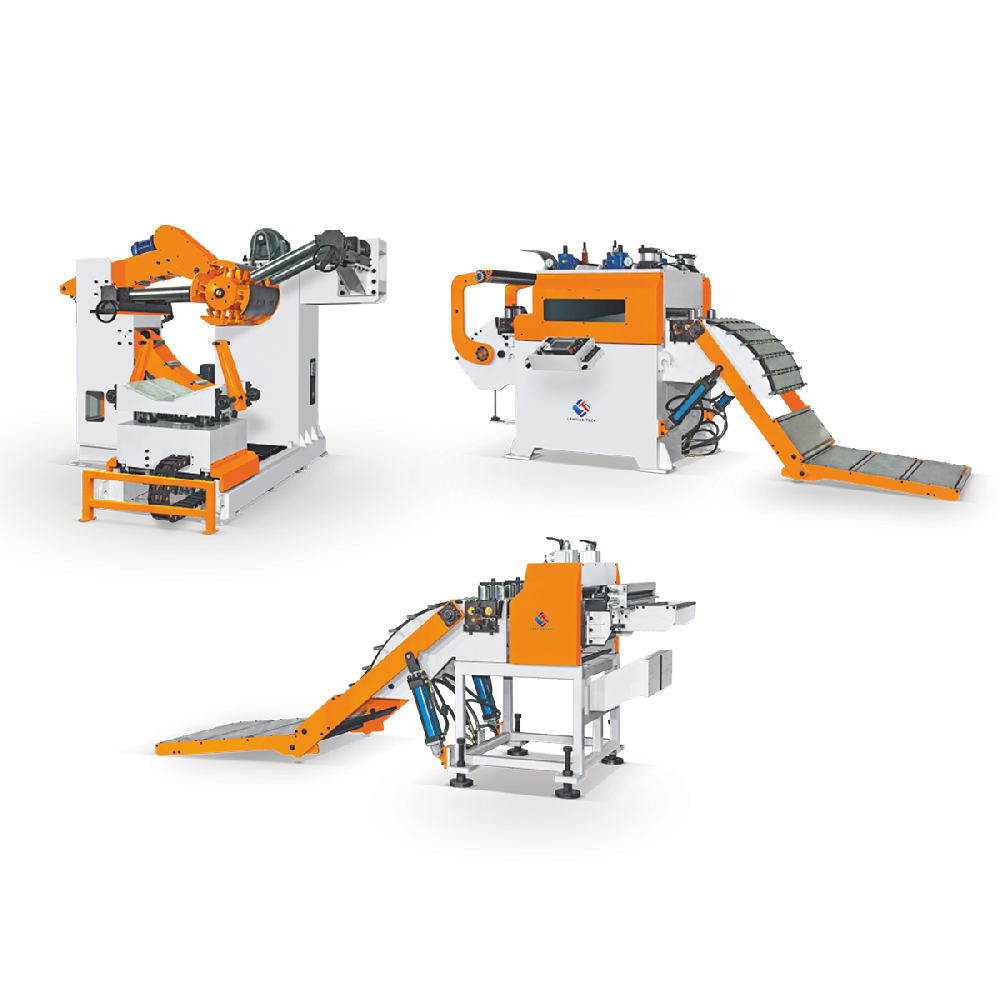

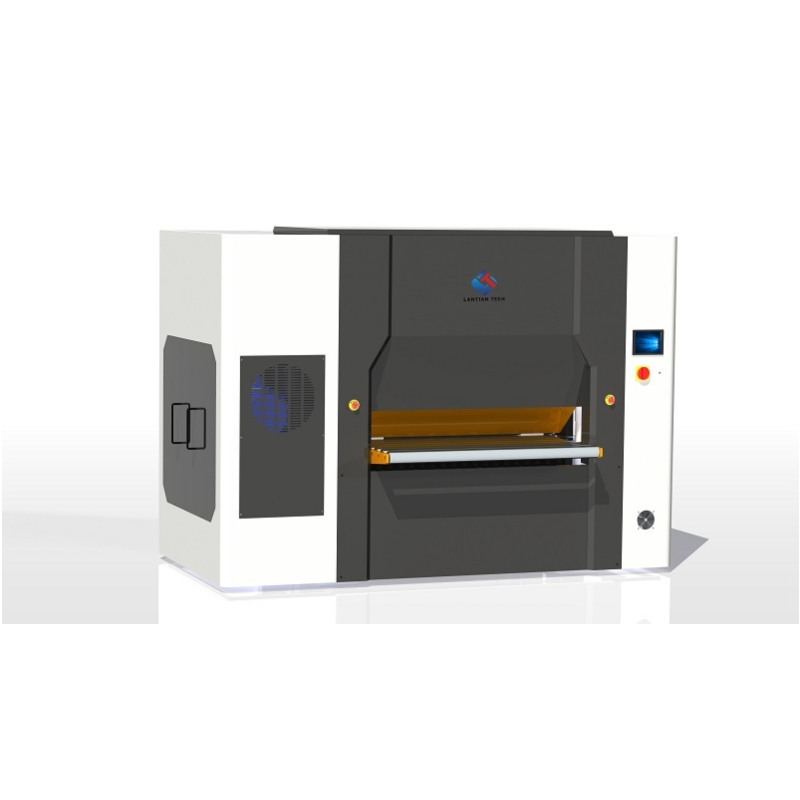

- Gambaran Keseluruhan

- Produk Disyorkan

| NCLT90P 4.5mm Bahan Kekuatan Tinggi | ||||||||

| Parameter teknikal | ||||||||

| Model | NCLT90P-600 | NCLT90P-800 | NCLT90P-1000 | NCLT90P-1300 | NCLT90P-1600 | NCLT90P-1800 | NCLT90P-2100 | |

| Parameter Penghurai | Garis Tengah Gegelung | 508/610 | ||||||

| Gegelung Max 0.D | 1500 | |||||||

| Berat Gegelung Max | 5000 8000 12000 15000 | |||||||

| Parameter Pelurus | Ketebalan bahan | 1.0-10.0 | ||||||

| lebar bahan | 100-600 | 100-800 | 10-1000 | 100-1300 | 100-1600 | 100-1800 | 100-2100 | |

| Tegangan Titik Alah Max | 675 | |||||||

| Kekuatan Tarikan Max | 1080 | |||||||

| Julat Ketebalan Optimum | 1.0-4.5 | |||||||

| Diameter roda penyusun | 90 | |||||||

| Rol penyusunan | Naik5/Turun4 | |||||||

| Parameter Pemakan | Kelajuan Pemberian | 16 | ||||||

| Panjang Pemakanan Maksimum | 0-9999.99 | |||||||

| Aras Pemakanan | (1200±100) Mengikut Kehendak Pelanggan | |||||||

| Parameter sistem | Motor Penghurai | 2.2 | 3.7 | 7.5 | 11 | |||

| Servo Motor | 15 22 30 | |||||||

| Pasukan kuasa | (380V/50HZ)3-Fasa 380V/50Hz atau mengikut permintaan pelanggan | |||||||

| Pasokan Udara | 0.4-0.6 MPa, 1.6³/min | |||||||

※Dalam jadual di atas, Julat Ketebalan Optimum dikira pada Yield Point Stress 245N/mm²(kekuatan tegangan 392N/mm²)

|

|

Aksesori standard: Penukaran automatik/manual Sistem kawalan fotoelektrik arka bahan Peranti brek cakera tekanan udara Ketinggian garisan suapan penyesuaian elektrik Pengesanan fotoelektrik bahan hujung Layar sentuh Mengembang dan mengecut secara hidraulik Lengan penekan tanpa kuasa Peranti panduan masukan perataan Pelarasan manual Tarikh pelarasan Paparan dial Tarikh pelarasan Warna cat yang dinyatakan |

aksesori pilihan: troli pemuatan Lengan penyokong bahan Lengan pengekang Pemberi minyak automatik Shear hidraulik Kepala boleh diangkat Penggelek kerja 6 ke atas 5 ke bawah Tarikh pelarasan pelarasan elektrik Tarikh pelarasan paparan berangka Tarikh pelarasan simpanan dan panggilan berangka ※ Konfigurasi khas juga boleh dibuat oleh syarikat kami |

|

|

|

|

|

|

|

|

| Daya pengangkutan yang kuat | Kebolehsuaian Luas | Prestasi kos tinggi | Struktur ringkas | Pekerjaan itu stabil | Tata Letak Fleksibel | Selamat dan boleh dipercayai | Mudah untuk diselenggara |