The Critical Role of Maintenance in Servo Hydraulic Leveling Operations

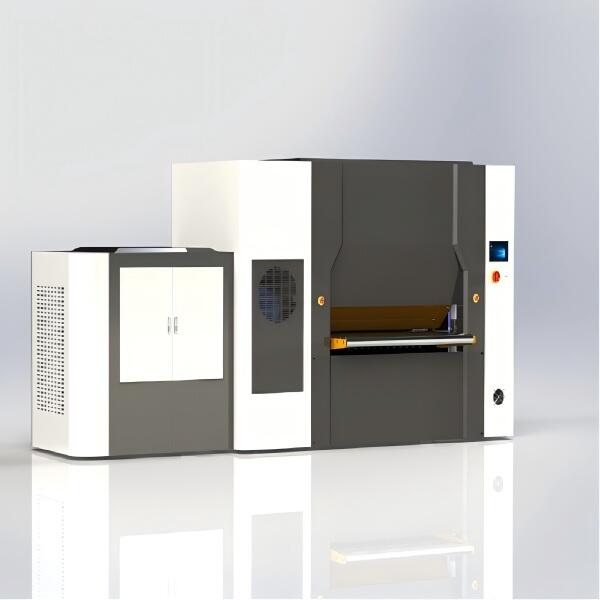

Servo Hydraulic Leveling Machines should be maintained to keep it working properly and to keep it operating for ages! These machines are complex machines which may require maintenance service at regular intervals in order to function properly. However, by having a routine maintenance plan in place, I can avoid any unscheduled downtime which could cost me time and money. The proactive maintenance contributes to extending the life of these machines, that their efficiency and reliability last over time.

These hydraulic systems rely on proper maintenance more than any other; given their work in precision operations used in applications such as manufacturing and construction. For example, the maintenance of systems keeps precision applications, such as needed in manufacturing, to be executed smoothly. Such high precision is important because small errors can amplify into very large errors in high-risk situations, even shutting down entire production lines. Regular checking and servicing of equipment such as pumps, motors and seals are important contributors to keeping this efficiency as high as possible.

Create a formal maintenance schedule A formal maintenance program is necessary to ensure safety and prevent problems related to equipment failure. Inspections for leaks, pressure testing and checking for wear are important for ensuring the safety of operators. This vigilance helps prevent incidents from occurring due to equipment malfunctions, and safeguards not only personnel, but also working area in which operations are being conducted. A properly serviced servo hydraulic system breaks down less and is safer for everyone who works around it.

Daily Inspection Protocols for Servo Hydraulic Leveling Machines

Routine inspections are crucial for maintaining servo hydraulic leveling machines' efficiency and reliability. By implementing daily inspection protocols, you can ensure machines function correctly, preventing unexpected failures.

Fluid Level and Quality Verification

Table 2Hydraulic systems Hydraulic tank Each hydraulic system also incorporates a hydraulic tank which holds hydraulic fluid (Fig the level should be checked about once a week. Everyday, I check to make sure the hydraulic fluids are in check, or you will have system failures. In addition checking the fluid for any discoloration or contamination will help to catch the degradation early. If any irregularities are discovered, reporting what is found, with corrective action taken in a timely manner, is necessary to ensure that everything continues to run smoothly.

Leak Detection and Prevention Strategies

I check at hydraulic connections and hoses for any wetness to prevent problems with fluid leakage. More sophisticated techniques, such as dye penetration or ultrasonic leak detection result in a more complete delineation of leaks. Also, the replacement of worn seals and fittings when unexpendable items are replaced also helps to proactively eliminate the possibility of leaks and to promote reliablility of the servo hydraulic system overall.

Noise and Vibration Monitoring Procedures

Another important element of keeping servo hydraulic leveling machines in good working order includes monitoring noise levels, since such noises could indicate mechanical failures. The use of vibration analysis tool provides a capability to diagnose the health of the servo systems and the components of it. By establishing baseline vibration data, I can routinely assess machine health and take steps to correct deviations to keep performance at its best.

Lubrication Best Practices for Moving Components

Bearing and Guide Rail Greasing Techniques

When it comes to greasing bearings and guide rails, the grease recommended by the equipment maker must be used. It makes certain that the lubricant is formulated for the materials and conditions inside the machine. And proper lubrication is carried out at the level prescribed in operating instructions and maintenance instruction, it is great conducive to arresting wear, lengething life and making the fan run reliably. To ensure lubrication is performed consistently, it also helps to create a lubrication schedule that outlines when and where lubrication is necessary. This method helps keep the parts in prime condition and it also extends the life of the components by minimizing friction and downtime.

Lubrication Frequency for Joints and Slides

Knowing the correct lubrication interval for joints and slides is a key factor to extend the operational life. Frequency would be determined by the use the equipment receives, or the condition of the environment, adjusting as required to match wear patterns. Although many of these lubricant-dependent machine components feature wear indicators, such as excessive resistance and noise, effectively diagnosing a machine lubrication problem is paramount as with any premature wear, a lubrication failure can result in extensive damage. Keeping a record of lubrication tasks, with all the details of the lubrication at one glance, helps to ensure compliance with maintenance schedules. This is not only useful for monitoring compliance, but also for future maintenance planning, as it allows analyses of usage and potential improvements.

Hydraulic System Maintenance Essentials

Maintaining a hydraulic system requires careful attention to several key components, ensuring smooth operations and preventing failures. Let me share some insights on essential maintenance practices that can extend the life of your hydraulic system.

Filter Replacement and Contamination Control

Reliable and frequent filter replacement is essential in hydraulic systems to avoid contamination. Replacing the filters on a regular schedule, as is recommended by the manufacturer and the hours the system is run, can help keep the system clean. Hydraulic filters must be checked often to prevent contamination, which may lead to part problems. Also, it is important to establish contamination control procedures to ensure hydraulic fluid cleanliness requirements...and to protect against future damage of the components.

Hydraulic Fluid Analysis and Replacement

Regular sampling of the hydraulic system fluids can aid in monitoring of contamination and degradation of the system over time. Set replacement time schedule using the test result and operating conditions for best performance. This ensures that the fluid always remains in its best possible condition resulting in efficient and durable operation of the system. Furthermore, fluid analysis data provides valuable information for making informed deicide when to overhaul and also in calculating budgets, ensuring maintenance is being performed based on actual component requirements.

Hose Integrity and Fitting Inspections

Hydraulic systems need to be checked routinely for wear and tear of hoses and connections. Inspect hoses for evidence of damage, such as bulging or cracking, and examine 'fittings' for signs of leaks, or pull on the fittings to make sure it hasn't come loose. Replace any worn out hoses or fittings to avoid catastrophic failures. These kind of preventive inspections can avoid potential system pressure loss and massive fluid leak, to keep fluid system efficiency and safety.

Servo Motor and Sensor Precision Care

Servo motors and sensors are vital components in hydraulic systems, requiring precise maintenance to ensure optimal performance. Let's delve into specific practices to maintain these components effectively.

Calibration and Alignment of Position Sensors

Position sensor calibration on a regular basis is necessary to ensure accurate readings and eliminate any drift over time. Using special tools we perform an alignment check and then verify it corresponding to manufacturer's requirements. We keep a record of all calibration work we do on this equipment: This establishes a detailed maintenance record on each system, which in return helps us (and you) track the sensor's performance and keep an eye on when calibrations should be scheduled (sensors eventually wear out).

Cleaning Protocols for Encoders and Feedback Systems

Implementing a thorough cleaning routine for encoders and feedback systems is crucial in preventing dust buildup and ensuring operational reliability. The use of appropriate, non-damaging cleaning agents helps maintain the integrity of sensitive electronic components. Logging cleaning activities provides a consistent service history and supports future maintenance planning.

Roller and Frame Alignment Procedures

Laser Alignment Verification Methods

Laser alignment tools are always a must for accurate wheel measurement in roller and frame alignment. This method promotes the ideal operation of the gear and accommodates roller and frame service life. In order to validate the success of these alignment modifications, benchmarking approaches can be adopted as a reference. To accomplish this, personnel should be properly trained on the use and advantages of laser alignment technology because it can greatly enhance data accuracy and maintenance productivity. That training enables the team to successfully drive alignment activities.

Corrective Adjustment Techniques for Wear Prevention

By being able to identify wear patterns this can lead to adjustments for correction on frames and rollers consequently reducing the probability of wear-out. When you use precision tools to make the adjustments that's dulling or wearing that edge of the metal out, you keep a lot of that operational integrity so that machine can keep running smooth and that machine can keep running well. Another important measure to reduce future wear risks is the implementation of preventive maintenance strategies. These measures not only extend the life of equipment, but also contribute to increased productivity through the reduction of unplanned stoppages. Routine inspections and adaptations allow equipment to operates at peak efficiency.

FAQ Section

Why is maintenance important for servo hydraulic leveling machines?

Maintenance ensures the optimal performance and longevity of these intricate systems, preventing malfunctions and potential financial consequences.

How does regular lubrication help in maintaining moving components?

Regular lubrication prevents wear and ensures smooth operation, contributing significantly to the efficiency and longevity of bearings, guide rails, joints, and slides.

What role does hydraulic fluid analysis play in maintenance?

Hydraulic fluid analysis helps monitor contamination and degradation, ensuring system reliability and supporting the longevity of the system.

Table of Contents

- The Critical Role of Maintenance in Servo Hydraulic Leveling Operations

- Daily Inspection Protocols for Servo Hydraulic Leveling Machines

- Lubrication Best Practices for Moving Components

- Hydraulic System Maintenance Essentials

- Servo Motor and Sensor Precision Care

- Roller and Frame Alignment Procedures

- FAQ Section