The Importance of Efficient Troubleshooting for Leveling Machines

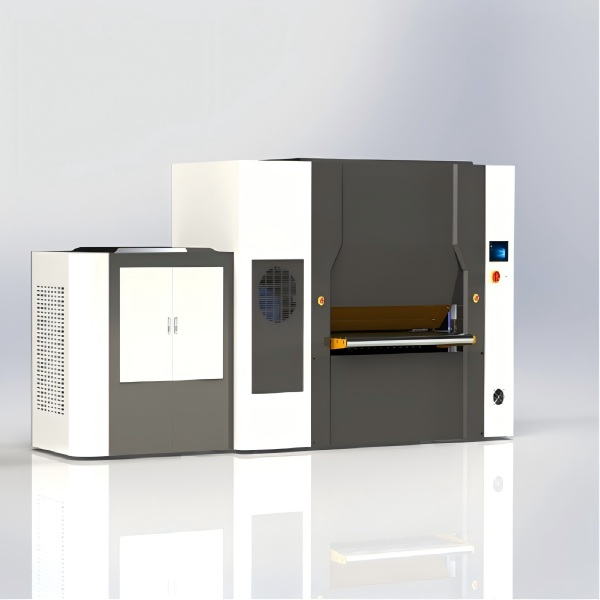

Leveling machines are essential tools in industries like metalworking, where precision is critical for producing quality products. However, like all machinery, leveling machines can experience issues that affect their performance. Troubleshooting these problems in a timely and efficient manner is key to maintaining productivity and minimizing downtime. This guide will explore common issues that operators may encounter with leveling machines and provide solutions to help restore optimal performance. By understanding the potential causes and remedies, manufacturers can reduce costly interruptions and keep their machines running smoothly.

Identifying and Addressing Alignment Issues

Misalignment of Rolls and Components

One of the most common issues that can affect the performance of a leveling machine is misalignment. Misalignment typically occurs when the leveling rolls or other components are not properly aligned, which leads to uneven pressure distribution across the material. This can result in inaccuracies such as uneven thickness, improper flatness, or distorted products. Misalignment can also cause unnecessary wear and tear on the machine, leading to more serious mechanical problems if left unaddressed.

To troubleshoot misalignment, begin by checking the position of the leveling rolls and other key components. Ensure that the rolls are correctly spaced and parallel to one another, and verify that any components responsible for material guidance are aligned properly. Misalignment can sometimes be the result of physical damage to the machine or loose parts, so inspect for any signs of wear, looseness, or deformation. Regular maintenance and periodic realignment of the rolls are essential steps in preventing misalignment from affecting the leveling machine's performance.

Adjusting for Uneven Roll Gap

The roll gap, or the distance between the leveling rolls, is a critical setting that influences the machine's leveling accuracy. An incorrect or uneven roll gap can result in material being over- or under-compressed, leading to inconsistent leveling and product quality. This issue is often seen when the gap has not been adjusted properly for the type of material being processed or when the gap changes during operation due to wear or mechanical failure.

To resolve uneven roll gap issues, carefully measure the gap using precision tools to ensure consistency across the entire width of the machine. Adjust the gap settings based on the material’s thickness and composition to ensure that the proper amount of pressure is applied. If the roll gap continues to fluctuate during operation, check for signs of wear or damage in the roll adjustment mechanisms. In some cases, recalibrating the machine or replacing worn parts may be necessary to maintain consistent leveling results.

Troubleshooting Pressure and Hydraulic System Problems

Low or Inconsistent Hydraulic Pressure

Hydraulic pressure plays a critical role in the leveling process, as it determines how much force is applied to the material being leveled. If the hydraulic pressure is too low or fluctuates inconsistently, the machine may not be able to apply uniform pressure, leading to uneven material leveling. Low hydraulic pressure can be caused by several factors, including leaks in the hydraulic system, a malfunctioning pump, or a failure in the pressure control system.

To troubleshoot hydraulic pressure issues, start by inspecting the hydraulic fluid levels and checking for any visible leaks in the system. If the fluid levels are low, top up the hydraulic fluid and inspect the machine for leaks. A malfunctioning pump or pressure valve may require repair or replacement. Additionally, check the pressure gauges and sensors to ensure they are calibrated correctly and functioning as intended. Regular maintenance of the hydraulic system, including fluid changes and component inspections, is essential for preventing pressure-related problems.

Excessive Pressure or Hydraulic Damage

Conversely, excessive hydraulic pressure can also cause problems, such as over-compression of the material, damage to the leveling machine's components, or even material distortion. This issue is often caused by faulty pressure regulation systems, a malfunctioning relief valve, or improper calibration of the hydraulic system. When pressure is too high, the material can become excessively flattened, leading to a loss of shape or quality.

To troubleshoot excessive hydraulic pressure, begin by inspecting the relief valve and pressure control system. The relief valve should open at the specified pressure limit, preventing the system from exceeding safe operating levels. If the relief valve is damaged or malfunctioning, replace it with a new one. Additionally, verify that the hydraulic system is properly calibrated and adjust pressure settings as needed to prevent over-compression. Regular pressure testing and calibration should be part of the machine's maintenance routine to prevent pressure-related issues.

Addressing Electrical and Control System Failures

Faulty Sensors and Feedback Loops

Leveling machines are often equipped with sensors that monitor parameters such as pressure, speed, and material thickness. These sensors provide real-time data that allows the machine to adjust its operations for optimal performance. However, if the sensors malfunction or fail, the machine may receive incorrect information, leading to inaccurate leveling and potential product defects. Faulty sensors are often the cause of issues like inconsistent material thickness, uneven pressure distribution, or improper roll gap adjustments.

To troubleshoot sensor issues, start by checking the wiring and connections to ensure that all components are properly connected. Inspect the sensors for any signs of damage or wear, and clean them if necessary. If the sensors are not responding correctly, they may need to be recalibrated or replaced. In some cases, the issue may lie within the feedback loop or control system, which may require a more in-depth diagnostic approach to identify and correct the problem.

Control System Malfunctions

Another common issue that can affect the performance of a leveling machine is a malfunction in the control system. The control system manages the operation of the machine, including speed, pressure, and roll gap adjustments. If the control system fails or experiences glitches, the machine may operate outside of its intended parameters, leading to inaccuracies in leveling or damage to the material. Common signs of a malfunctioning control system include erratic machine behavior, unresponsive adjustments, or error codes on the display.

To troubleshoot control system issues, begin by checking the electrical connections and ensuring that the system’s wiring is intact. Inspect the control panel and software for any error codes or malfunctions. If the control system is digital, it may require a software reset or an update to restore normal operation. For more complex issues, consulting the machine’s technical manual or a professional technician may be necessary to diagnose and resolve the problem.

Preventing Future Issues and Maintaining Machine Performance

Regular Maintenance and Calibration

Preventing issues with a leveling machine often comes down to regular maintenance and calibration. Many common problems, such as misalignment, inconsistent hydraulic pressure, and sensor malfunctions, can be avoided by adhering to a strict maintenance schedule. This includes routine inspections, lubrication of moving parts, hydraulic fluid changes, and calibration of sensors and pressure settings. Performing these tasks at regular intervals ensures that the machine continues to operate at peak performance and helps identify potential issues before they lead to major problems.

Training Operators and Improving Operational Procedures

In addition to machine maintenance, proper operator training is essential for preventing and troubleshooting issues. Well-trained operators are more likely to identify problems early and take the necessary steps to resolve them quickly. Ensuring that operators understand the machine's capabilities, settings, and troubleshooting procedures can significantly reduce the likelihood of issues arising and improve the overall efficiency of the leveling process. Implementing clear operational procedures, including proper material handling, speed adjustments, and pressure control, can also minimize the occurrence of issues during machine operation.

FAQ

What are some common issues with leveling machines?

Common issues with leveling machines include misalignment of the rolls, inconsistent hydraulic pressure, faulty sensors, and malfunctions in the control system. These problems can lead to uneven leveling, inaccurate thickness, and material distortion.

How can I fix a misaligned leveling machine?

To fix a misaligned leveling machine, first check the alignment of the rolls and other key components. Ensure that the rolls are properly spaced and parallel to one another. If necessary, realign the rolls and perform regular maintenance to prevent misalignment from recurring.

Why is hydraulic pressure important for leveling accuracy?

Hydraulic pressure determines the amount of force applied to the material being leveled. Inconsistent or incorrect hydraulic pressure can lead to uneven leveling, material damage, or poor product quality. Proper pressure control is essential for maintaining accuracy in the leveling process.

How can I prevent control system malfunctions?

Prevent control system malfunctions by regularly inspecting the wiring, checking for error codes, and ensuring that the control panel and sensors are functioning properly. Perform software updates or resets as needed and consult a professional technician for complex issues.