Understanding the Revolutionary Impact of Modern CNC Leveling Technology

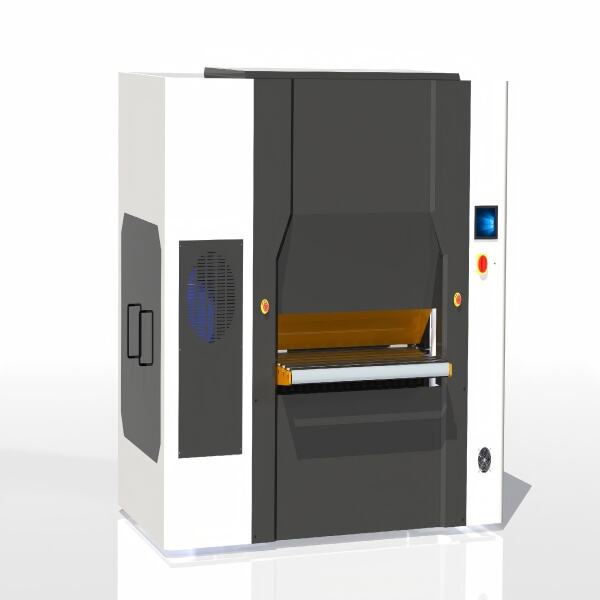

The manufacturing industry has witnessed a remarkable transformation with the introduction of CNC precision leveling machines. These sophisticated systems have redefined the standards of material processing, offering unprecedented control over flatness and dimensional accuracy. By integrating advanced computer numerical control with precision engineering, these machines deliver consistent, high-quality results that were previously unattainable through conventional leveling methods.

At its core, a CNC precision leveling machine represents the pinnacle of automated flatness correction technology. The system employs multiple independently controlled rollers, advanced sensors, and sophisticated software algorithms to analyze and correct material deviations with microscopic precision. This level of control ensures that every piece of processed material meets exact specifications, dramatically reducing waste and improving overall production efficiency.

Core Components and Technical Excellence

Advanced Roller Configuration System

The heart of a CNC precision leveling machine lies in its innovative roller configuration. These machines typically feature between 9 and 17 precisely engineered leveling rollers, each independently adjustable through sophisticated servo motors. The rollers work in perfect harmony to apply calculated pressure patterns across the material surface, effectively eliminating waves, buckles, and other surface irregularities.

The spacing and diameter of these rollers are carefully optimized to handle various material thicknesses and types. Modern CNC precision leveling machines can process materials ranging from thin foils to thick plates, maintaining exceptional flatness tolerances throughout the entire spectrum of applications.

Intelligent Control Systems

The machine's brain consists of advanced control systems that continuously monitor and adjust the leveling process. High-resolution sensors measure material properties in real-time, while sophisticated algorithms calculate the optimal roller positions for achieving desired flatness. This intelligent system ensures consistent results regardless of material variations or operating conditions.

The control interface provides operators with comprehensive data visualization and adjustment capabilities, allowing for fine-tuning of processing parameters to achieve optimal results. Real-time feedback mechanisms enable immediate corrections, virtually eliminating the risk of processing errors.

Precision Enhancement Capabilities

Material Stress Management

CNC precision leveling machines excel in managing internal material stresses. Through calculated deformation patterns, these systems can effectively neutralize residual stresses that cause warping and distortion. This capability is particularly valuable when processing high-strength materials or components destined for precision applications.

The machine's ability to maintain consistent pressure distribution ensures uniform stress relief across the entire material width, resulting in exceptionally flat products that maintain their shape even after subsequent processing steps.

Dimensional Stability Control

Modern CNC precision leveling machines incorporate advanced measurement systems that continuously monitor material dimensions during processing. This real-time dimensional control ensures that finished products meet exact specifications, crucial for applications in aerospace, automotive, and precision manufacturing sectors.

The system's ability to maintain tight dimensional tolerances significantly reduces the need for secondary processing operations, leading to substantial time and cost savings in the production workflow.

Production Efficiency and Quality Assurance

Automated Quality Control Integration

CNC precision leveling machines feature integrated quality control systems that automatically verify product specifications during processing. Advanced scanning technologies measure surface flatness, thickness variation, and other critical parameters in real-time, ensuring that every processed piece meets predetermined quality standards.

This automated quality assurance significantly reduces inspection time and eliminates the possibility of human error in quality assessment. The system generates detailed quality reports for each processed batch, providing valuable documentation for quality certification and process optimization.

Production Throughput Optimization

The advanced automation capabilities of CNC precision leveling machines dramatically improve production efficiency. These systems can maintain high processing speeds while delivering superior flatness results, effectively increasing overall throughput without compromising quality standards.

Smart scheduling algorithms optimize material flow through the machine, minimizing setup times between different material types or thickness ranges. This intelligent production management leads to significantly higher operational efficiency compared to conventional leveling systems.

Industry Applications and Benefits

High-Precision Manufacturing Sectors

In industries such as aerospace and medical device manufacturing, CNC precision leveling machines play a crucial role in ensuring component quality. These machines process materials to extremely tight tolerances, meeting the stringent requirements of critical applications where material flatness directly impacts product performance and safety.

The ability to consistently achieve superior flatness results makes these machines indispensable in the production of precision components for advanced technology applications, from satellite components to surgical instruments.

Automotive and Industrial Applications

The automotive industry relies heavily on CNC precision leveling machines for processing body panels, structural components, and various other metal parts. The machines' ability to handle different material grades and thicknesses while maintaining consistent quality makes them ideal for high-volume automotive production environments.

Industrial manufacturers benefit from the enhanced material properties and improved downstream processing capabilities that precision-leveled materials offer, resulting in higher quality finished products and reduced production costs.

Frequently Asked Questions

What materials can be processed using a CNC precision leveling machine?

CNC precision leveling machines can process a wide range of materials including steel, aluminum, copper, and various alloys. They are capable of handling material thicknesses from thin foils to thick plates, typically ranging from 0.1mm to 50mm, depending on the specific machine model and configuration.

How does CNC precision leveling improve overall product quality?

CNC precision leveling enhances product quality by eliminating flatness defects, managing internal stresses, and ensuring consistent material properties. The process results in improved dimensional stability, better surface finish, and enhanced material characteristics that benefit subsequent manufacturing operations.

What maintenance requirements are associated with CNC precision leveling machines?

Regular maintenance includes roller inspection and cleaning, calibration of control systems, and verification of sensor accuracy. Modern machines feature predictive maintenance capabilities that alert operators to potential issues before they impact production, minimizing unexpected downtime and ensuring optimal performance.