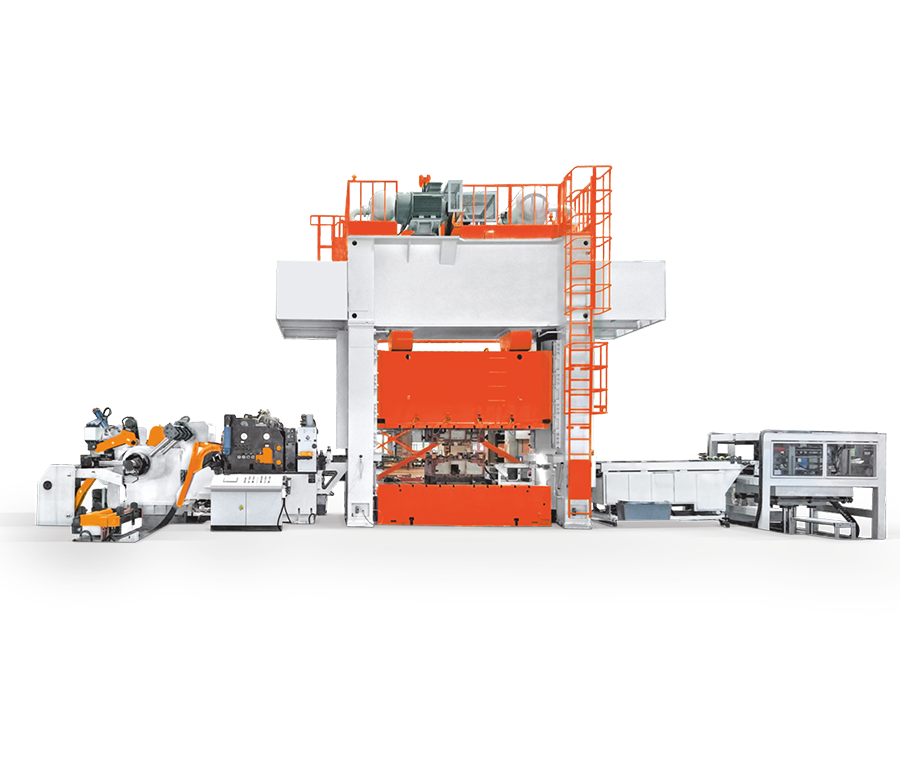

Large Uncoiling Blanking Production Line

The large-scale open-roll blanking production line is an important equipment for metal sheet processing.First,the uncoiler will uncoil the metal coil,the plate is leveled by a leveling machine.Then,the feeding device conveys the leveled plate to the die for cutting,the blanking die shears the plate under the action of the press,process the plates into the required shape of the parts.Finally,the stacking device stacks the parts after they are discharged.

- Overview

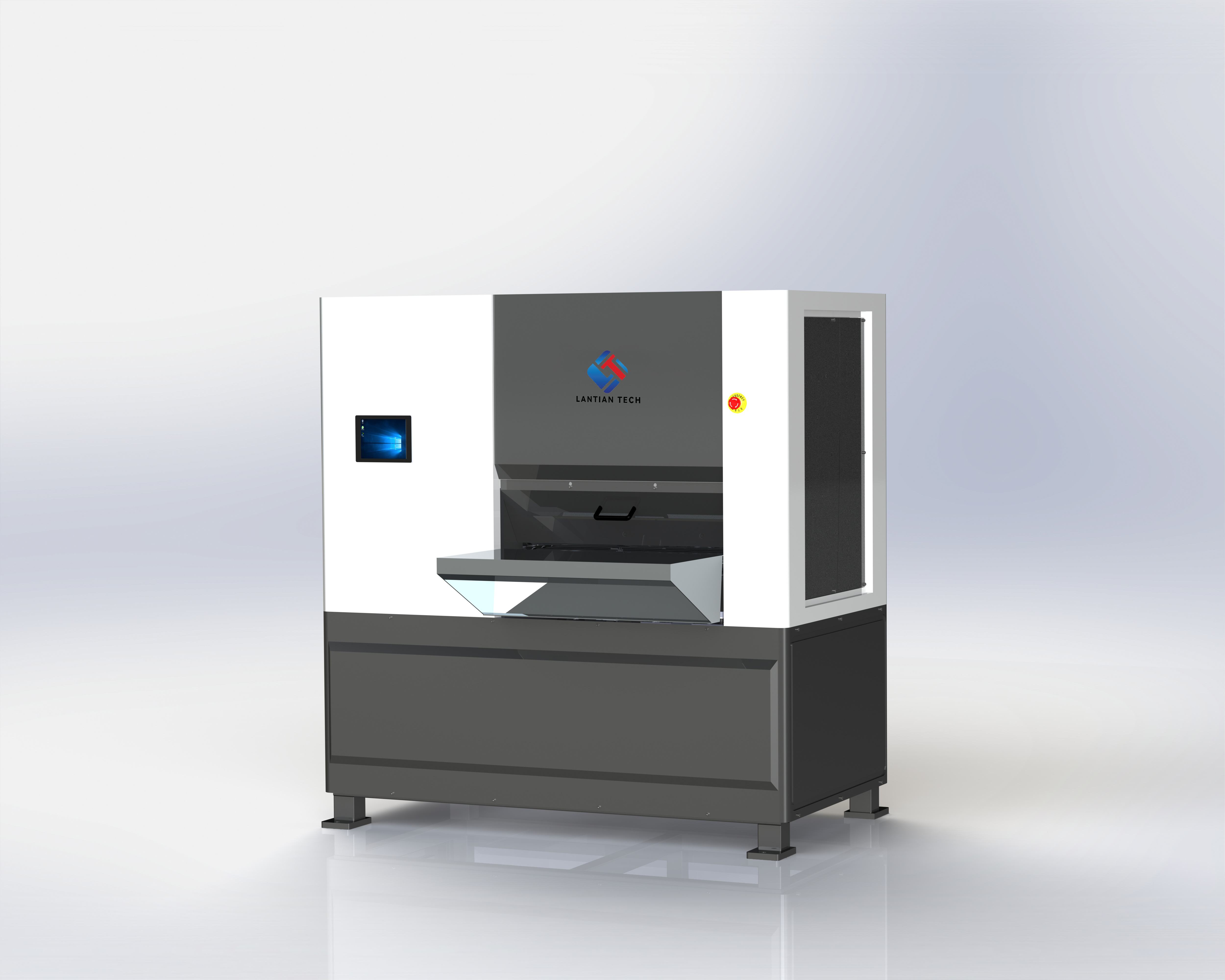

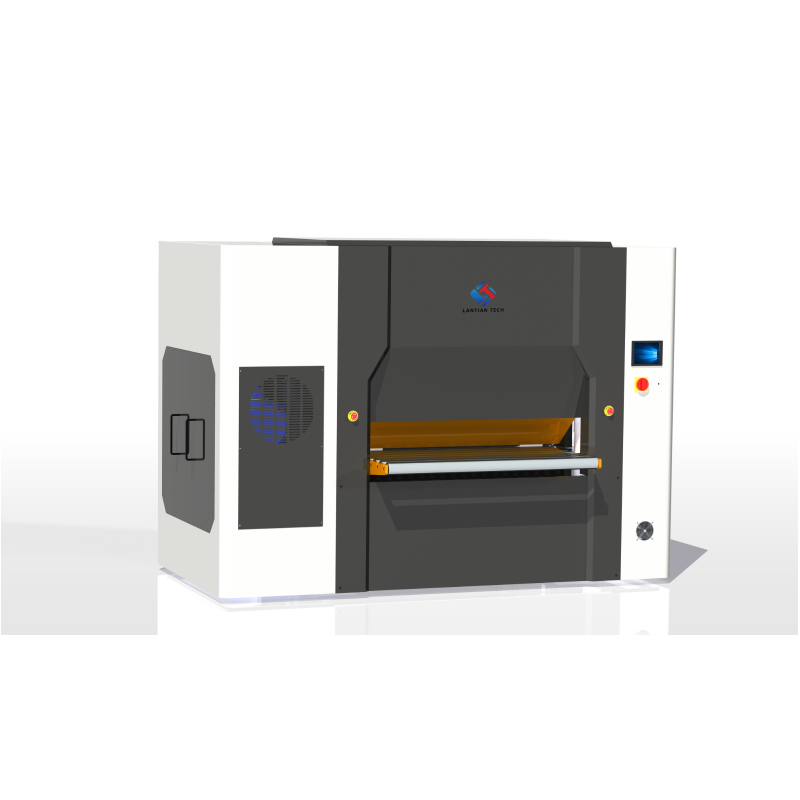

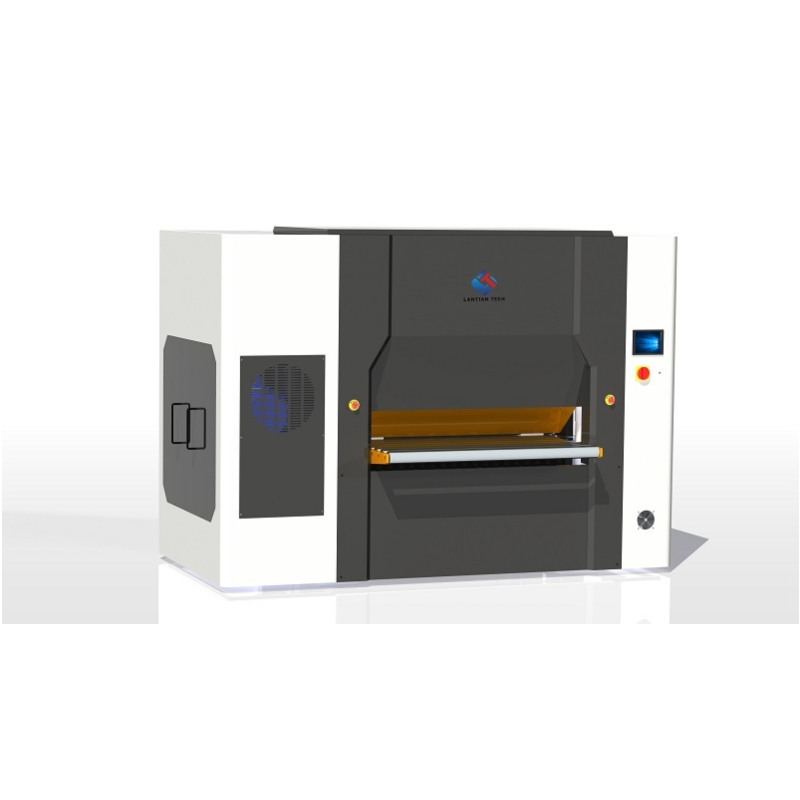

- Recommended Products