Understanding the Power of Modern Hydraulic Leveling Technology

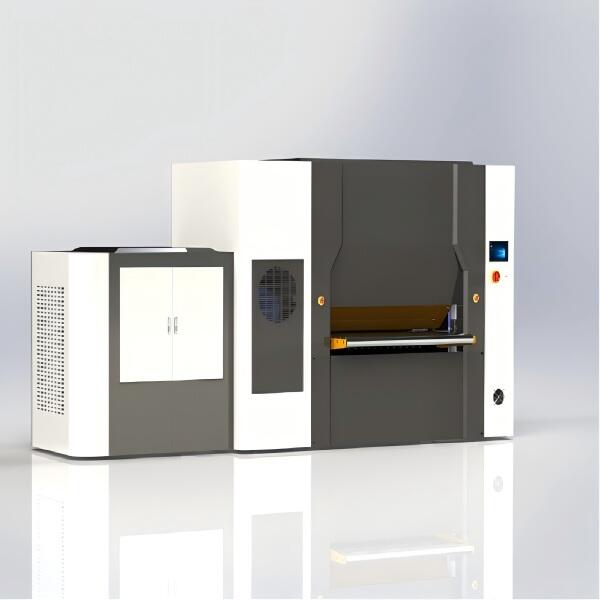

The evolution of industrial flattening technology has reached new heights with the advancement of hydraulic leveling machines. These sophisticated pieces of equipment have revolutionized the metal processing industry by delivering unprecedented precision and consistency in material flattening operations. Through the strategic application of hydraulic pressure and intelligent control systems, these machines transform irregular surfaces into perfectly level sheets with remarkable efficiency.

A hydraulic leveling machine represents the pinnacle of flattening technology, combining robust mechanical engineering with precise hydraulic controls. The system's ability to maintain constant pressure while adjusting to material variations makes it indispensable in modern manufacturing processes. From automotive components to construction materials, these machines ensure the highest quality standards are met consistently.

Core Components and Mechanical Design

Advanced Hydraulic Systems Integration

At the heart of every hydraulic leveling machine lies a sophisticated network of hydraulic cylinders, pumps, and control valves. These components work in perfect harmony to distribute pressure evenly across the material surface. The hydraulic system maintains precise control over the leveling rolls, automatically adjusting pressure levels to accommodate varying material thicknesses and properties.

The integration of high-capacity hydraulic pumps ensures consistent pressure delivery throughout the leveling process. Modern machines feature multiple independent hydraulic zones, allowing for differential pressure application across the width of the material. This zonal control system enables the machine to address localized irregularities while maintaining overall flatness.

Precision-Engineered Leveling Rolls

The leveling rolls in a hydraulic leveling machine are manufactured to exacting specifications, featuring specially hardened surfaces and optimal diameter ratios. These rolls are arranged in a carefully calculated pattern that maximizes the machine's ability to eliminate both major and minor surface imperfections. The roll spacing and configuration are designed to progressively work the material through increasingly tight tolerances.

Advanced coating technologies and surface treatments ensure the rolls maintain their precision over extended operating periods. The hydraulic leveling machine's roll design incorporates sophisticated bearing systems that minimize friction and wear while maintaining precise alignment throughout the leveling process.

Operational Excellence and Control Systems

Automated Process Management

Modern hydraulic leveling machines incorporate advanced control systems that continuously monitor and adjust operating parameters. These systems utilize real-time feedback from multiple sensors to maintain optimal leveling conditions. The integration of programmable logic controllers (PLCs) enables operators to store and recall specific processing parameters for different materials and applications.

The automated management system ensures consistent results by maintaining precise control over roll gaps, line speed, and hydraulic pressure. This level of automation reduces operator dependency while improving overall productivity and material yield. The system can quickly respond to variations in material properties, ensuring uniform flatness across entire production runs.

Quality Monitoring and Feedback

State-of-the-art hydraulic leveling machines feature sophisticated quality monitoring systems that provide continuous feedback on leveling performance. These systems employ laser measurement technology and advanced sensors to verify material flatness in real-time. The data collected helps operators optimize machine settings and maintain consistent quality standards.

The integration of quality monitoring systems with the machine's control interface allows for immediate adjustments when deviations are detected. This proactive approach to quality control minimizes waste and ensures that finished products meet or exceed specification requirements.

Material Processing Capabilities

Versatility in Material Handling

A hydraulic leveling machine demonstrates remarkable versatility in processing various materials. From thin gauge sheets to heavy plate steel, these machines can effectively handle a wide range of material thicknesses and types. The hydraulic system's ability to precisely control pressure makes it possible to process both soft and hard materials without surface damage.

The machine's design accommodates different material widths and configurations, making it suitable for diverse industrial applications. Special features such as quick-change roll systems and adjustable entry guides facilitate efficient material handling and minimize setup times between different production runs.

Enhanced Surface Quality Results

The superior flattening capabilities of hydraulic leveling machines result in exceptional surface quality improvements. The controlled application of pressure eliminates common defects such as edge waves, center buckles, and coil set while preserving the material's surface finish. This precision ensures that processed materials meet the most demanding quality standards.

Through careful control of processing parameters, these machines can achieve flatness tolerances that were previously unattainable with conventional leveling methods. The combination of precise hydraulic control and advanced roll technology produces consistently superior results across various material grades and specifications.

Frequently Asked Questions

What maintenance requirements do hydraulic leveling machines have?

Regular maintenance of a hydraulic leveling machine includes checking hydraulic fluid levels and quality, inspecting roll surfaces for wear, calibrating control systems, and ensuring proper alignment of all components. Preventive maintenance schedules typically include daily inspections, weekly system checks, and comprehensive quarterly servicing to maintain optimal performance.

How does material thickness affect leveling performance?

Material thickness directly influences the hydraulic pressure settings and roll gap adjustments required for optimal leveling. The machine's control system automatically adapts these parameters based on material specifications, ensuring consistent results across varying thicknesses. Thicker materials generally require higher hydraulic pressures and larger roll diameters for effective processing.

What advantages do hydraulic leveling machines offer over mechanical levelers?

Hydraulic leveling machines provide superior control over the leveling process through precise pressure regulation, automated adjustment capabilities, and real-time quality monitoring. They offer greater versatility in material processing, improved consistency in results, and better handling of varying material properties compared to traditional mechanical levelers. The hydraulic system also allows for more gentle material treatment, reducing the risk of surface damage.