What Is a Leveling Machine?

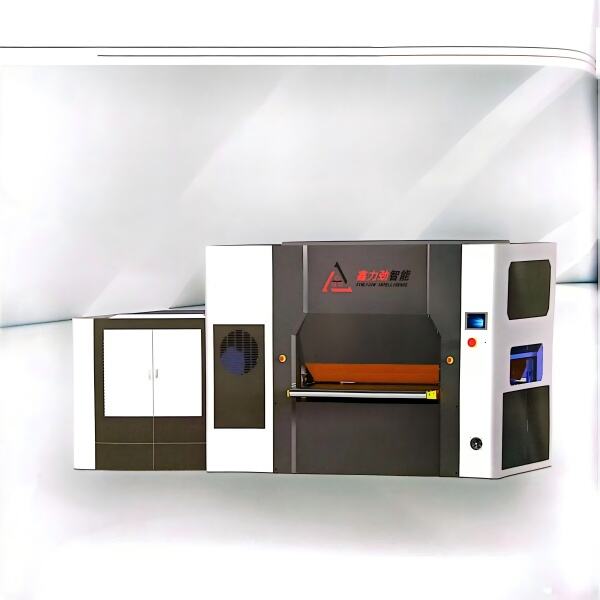

How Leveling Machines Work

Leveling machines work by running metal sheets through multiple rollers that apply just the right amount of pressure to smooth out and flatten the material. This whole process helps fix problems like warped edges, bent sections, and all sorts of surface bumps, so what comes out has uniform thickness and really good flatness across the board. Better quality leveling equipment typically uses either hydraulics or mechanical systems to adjust pressure settings depending on what kind of material they're working with and how thick it is. When manufacturers can take those rough, uneven sheets and turn them into something flat and even, it makes everything else in production run much smoother and leads to better finished products overall. As technology keeps improving, these leveling machines just keep getting more important for anyone serious about making precision cuts and maintaining high standards in metal sheet manufacturing.

Key Components and Operational Benefits

Leveling machines have three main parts working together feed rollers, actual leveling rollers, and smart control systems that watch over how flat things get during processing. When all these parts work right, they bring about some real advantages for operations. Surfaces come out smoother and measurements are much more accurate than before. What does this mean practically? Less time spent on machining and money saved in the long run. Some studies point to around 20 to 30 percent boost in productivity when companies adopt leveling machines. Look at what happens in different sectors like cars being made, buildings going up, or big industrial equipment production. The difference is noticeable. Factories that bring these machines into their workflow see better results day after day while keeping pace with market demands that keep changing faster than ever.

Automotive Industry: Precision Flattening for Metal Parts

Critical Role in Stamping and Frame Production

Leveling machines play a vital role in the automotive sector when it comes to getting metal sheets ready for stamping operations. They flatten out those sheets so they can be cut and shaped accurately, something that matters a lot when making car parts that need to fit together just right every time. When these machines do their job properly, the resulting flatness affects how strong the vehicle frame ends up being, which obviously impacts safety as well as how the car performs on the road. Research shows that better flatness in stamped components means less waste of materials during production, saving manufacturers money in the long run. Some factories report cutting down on scrap by around 15% after upgrading their leveling equipment.

Materials Processed: Steel, Aluminum, and Advanced Alloys

Leveling machines work really well when it comes to processing all sorts of materials that the automotive industry needs, like steel, aluminum, and those newer alloy mixes they've been developing lately. The reason these particular metals stick out is because they just don't break down easily and can be shaped into almost anything needed for car production. With today's leveling tech, machines can handle pretty much any material thrown at them whether it's thin sheet metal or something thicker with different strength characteristics. What makes this process so valuable is how it actually makes metal parts last longer. When manufacturers level metals properly, they're not just getting better surfaces but also enhancing how strong those parts will be over time. This means cars end up with components that hold up better against wear and tear, which everyone in the business knows translates to fewer repairs down the road.

Construction and Steel: Preparing Sheets and Plates

Applications in Structural Steel Fabrication

Leveling machines are really important for construction work, particularly when it comes to structural steel fabrication. They help make sure those metal sheets and plates actually match what engineers specify in their blueprints. When these machines do their job right, they flatten out materials so welders and assemblers have something reliable to work with. That makes all the difference on actual building sites and big infrastructure projects. Studies show that proper metal flattening cuts down on construction mistakes around 15 percent, which means projects finish faster and stay within budget more often. For fabricators working on steel structures, getting this step right matters a lot because poor material prep leads to wasted time and money. Most experienced contractors know from hard lessons that investing in good leveling equipment pays off in both quality and efficiency over the long run.

Enhancing Durability for Infrastructure Projects

When construction workers use leveling machines on steel sheets, they get much better flatness and surface quality than traditional methods allow. This matters a lot for big infrastructure projects where even small imperfections can cause problems down the road. Steel that's properly leveled lasts longer too, making buildings and bridges safer while still passing all those tough building codes. Some studies show that spending money on good leveling tech actually extends the life of infrastructure by around 30 percent, which cuts down on repairs later on. The real benefit comes from how flat everything ends up being. Structures built this way hold up against weather changes, traffic vibrations, and other stresses without breaking down as quickly, so cities end up with stronger, more sustainable buildings in the long run.

Appliance Manufacturing: Ensuring Smooth Surfaces for Assembly

Eliminating Imperfections in Stainless Steel Components

For appliance manufacturers, getting those stainless steel surfaces right without any defects matters a lot. Leveling machines do most of the heavy lifting here, knocking out those pesky dents and bends that would otherwise ruin how appliances look and perform. When surfaces are properly leveled, it really makes a difference not just visually but also functionally speaking. Appliances with smoother surfaces tend to last longer and work better overall. According to some market research, brands that focus on quality surface finishes report around 25% fewer returns and customer complaints. That statistic alone shows why investing time and resources into proper leveling techniques pays off for businesses looking to build lasting relationships with their customers while keeping repair costs down.

Impact on Production Efficiency and Product Lifespan

Using leveling machines does more than just make parts look better on the surface; these tools actually boost how fast things get made in the factory. When components are properly flattened, they slot together much smoother during assembly, cutting down hours that would otherwise be wasted on adjustments. Faster assembly means quicker turnaround times, which is great news for anyone tracking production metrics. Plus, appliances built with properly leveled parts tend to last longer too. Refrigerators, washing machines, even microwaves all benefit from reduced stress points throughout their structure. According to recent industry reports, companies that upgrade to modern leveling tech often see around 15% improvement in daily output numbers. That kind of boost makes a real difference when trying to meet quarterly goals while keeping costs under control.

Aerospace and Shipbuilding: High-Standard Metal Processing

Meeting Rigorous Quality Control Standards

For companies working in aerospace and shipbuilding sectors, sticking to strict quality control isn't just important it's absolutely essential when talking about safety and how well things perform. Leveling machines have become must-have equipment across these fields because they help ensure metal components actually meet those tough requirements. These machines can flatten surfaces with incredible accuracy, allowing manufacturers to hit those tight tolerance specifications that matter so much in industries where even small errors could lead to major problems. Industry insiders point out that getting certified by top aviation and maritime regulatory bodies usually hinges on the quality of materials being worked with. Real world experience shows that better flattening processes tend to cut down on failures significantly. That's why investing in good quality leveling equipment remains a smart move for any manufacturer serious about maintaining their reputation and keeping operations running smoothly.

Processing High-Performance Materials like Titanium

Leveling machines play a key role when working with tough materials like titanium, known for its tricky nature because of how it behaves under heat and pressure. The right equipment delivers the accuracy needed to boost the performance of parts made from this metal, something many engineers appreciate since titanium offers incredible strength while being surprisingly light. Flattening these components makes all the difference too, as it actually improves those mechanical characteristics that matter so much in aircraft construction. Studies point out that getting the leveling right extends how long these parts last before they start showing wear and tear. For planes and spacecraft manufacturers, this matters a lot since stronger, longer lasting materials mean safer flights and fewer maintenance stops along the way.

FAQ

Why are leveling machines important in manufacturing?

Leveling machines ensure metal sheets are flat and defect-free, enhancing production efficiency and quality across various industries.

What materials can leveling machines process?

Leveling machines can process a range of materials including steel, aluminum, and advanced alloys, adapting to diverse specifications.

How do leveling machines improve construction projects?

By providing precise flatness and surface finish, leveling machines reduce construction errors, improve timelines, and enhance structural durability.

Are leveling machines used in the aerospace industry?

Yes, they are crucial for ensuring the precision and durability of components made from high-performance materials, like titanium, in aerospace applications.