NCLT50 3.2mm Нисэх материал

Төрлөөр:

Ердийн бага нүүрстөрөгчтэй ган, цинкийн давстай хавтан, нимгэн хавтан, нержавейка ган болон бусад материалд тохиромжтой;

Ажиллах роликыг гулгах гангаар хийж, гангийн хатуулагийг HRC60±2 болтол нь хромын давхаргаар бүрсэн байна;

Бүрэн багцын Siemens сервожуудыг ашиглан өндөр нарийвчлалтай оролт хийх боломжийг хангана;

Хүнлэг дизайн, аюулгүй байдлын хамгаалалтын системтэй нэгдүүлэн ажил эрхлэгчдийн ажиллагаанд тохиромжтой;

Энэ загварын ролоны системийн бүтцийг тийм байдлаар зохион бүтээсэн бөгөөд ролон тус бүрийг тусдаа татан гаргаж солих боломжтой байна;

- Ерөнхий мэдээлэл

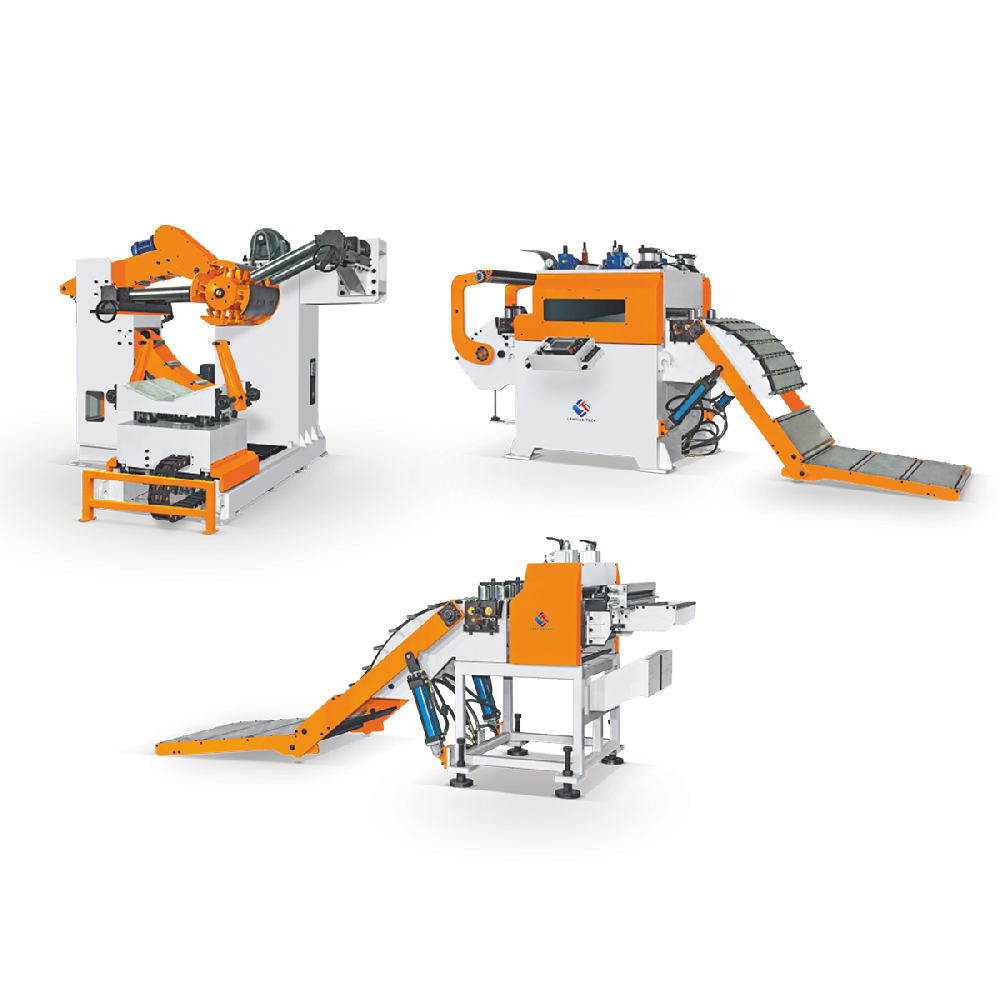

- Зөвлөж буй бүтээгдэхүүн

| NCLT50 3.2mm Нисэх материал | ||||||

| Техникийн үзүүлэлт | ||||||

| Загвар | NCLT50-400 | NCLT50-600 | NCLT50-800 | NCLT50-1000 | NCLT50-1300 | |

| Урлалтын параметр | Ороомог I.Д | 508/610 | ||||

| Хамгийн том ороомог 0.Д | 1400 | |||||

| Хамгийн их ороомог жин | 3000 5000 8000 | |||||

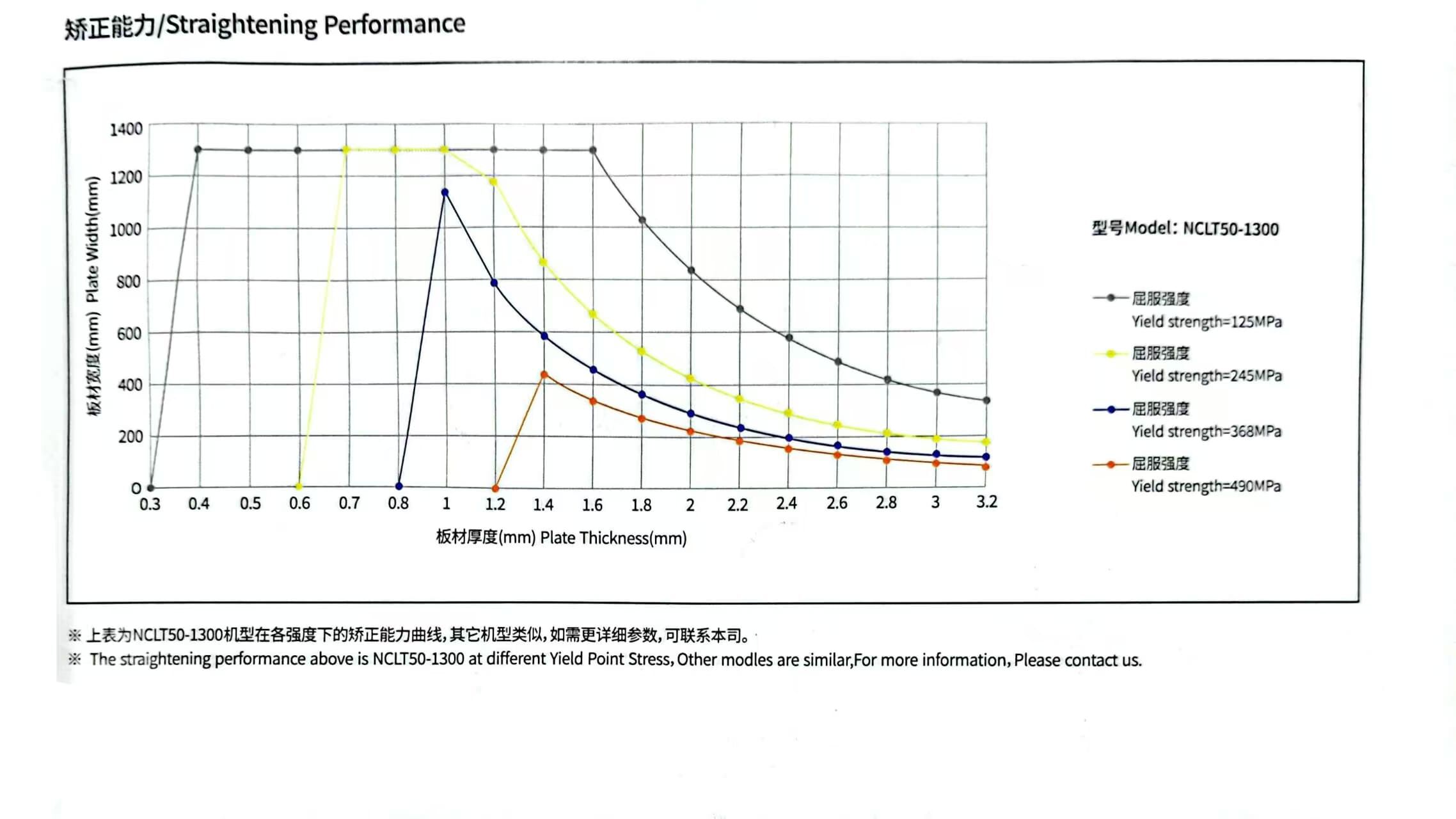

| Тэгшлэгч параметр | Усны материалын үзүүлэлт | 0.3-3.2 | ||||

| материалын өргөн | 70-400 | 70-400 | 70-800 | 70-1000 | 70-1300 | |

| Хамгийн дээд хүчний хэмжээ | 490 | |||||

| Хамгийн дээд таталтын бат бөх байдал | 780 | |||||

| Дээд зэргийн зузааны муж | 0.5-1.8 | |||||

| Шулуун байлга нь хэмжээний диаметр | 48 | |||||

| Зогсоо хөдөлгөөнтөөс засах | Дээш5/Доош4 | |||||

| Хооллох параметр | Тэжээлийн хурд | 16-24 | ||||

| Хамгийн их оруулах урт | 0-9999.99 | |||||

| Хооллох түвшин | (1200±100) Үйлчлэгчийн шаардлагын дагуу | |||||

| Системийн параметр | Осолтны хөдөлгүүр | 1.5 | 2.2 | 3.7 | ||

| Серво мотор | 2.9 4.4 5.5 | |||||

| Эрчим хүчний хангамж | (380V/50HZ)3-фаз 380V/50Hz эсвэл харилцагчийн хүсэлтийн дагуу | |||||

| Хоолой орох | 0.4-0.6 MPa,0.5³/мин | |||||

※Дээрх хүснэгтэнд Оптимал зузааны муж нь 245N/мм² уян хатан байдлын хязгаарт (татах бат бөхийн чадал 392N/мм²) бодож гаргасан

|

|

Стандарт хэрэглэгдэхүүн: Автомат/гар ажиллагааны шилжүүлэгч Материалын нум фотоэлектрон хяналтын систем Агаарын даралттай дискэн тормозны төхөөрөмж Хооллох шугамын өндрийн цахилгаан зохицуулга Эцсийн материал дээрх фотоцахилгааны илрүүлэгч Нууц screen Гидравлик тэлэлт ба нэгдэл Цахилгаан хөтлөгч биш даралт үүсгэгч төхөөрөмж Тэнцвэржүүлэгч оролтын удирдах төхөөрөмж Зохицуулгын өдрийг гар аргаар зохицуулах Зохицуулгын өдрийг циферблат дээр харуулах Тодорхойлсон будгийн өнгө |

0пциональ аксессуар: ※ Компанийн бид өөрчлөлтийг тусгай захиалгаар хийх боломжтой |

|

|

|

|

|

|

|

|

| Хүчтэй зөөвөрлөх хүч | Илүү их хэрэгслэх боломжтой | ӨНДӨР ЗАРДАЛЫН ҮР ДҮН | Хялбар байгууламж | Ажил нь тогтвортой байна | Шилдэг байршил | Аюулгүй, найдвартай | Арчлахад хялбар |